Today’s oilfield landscape is increasingly about maximizing economics by implementing technologies that focus on enhancing the value of existing assets rather than drilling new wells.

Historically, operators have been able to identify and recover only a fraction of the oil in their reservoirs, especially as fields mature. However, technological advances are expanding opportunities to identify and recover bypassed oil and/or locate previously unknown reserves through cased wells.

This capability results in a greater understanding of how the reservoir behaves over time and through multiple phases of development, eliminates guesswork and significantly reduces the production of undesirable water or gas while improving oil recovery. With more accurate, reliable reservoir knowledge, operators can devise a more informed and effective production strategy to boost hydrocarbon recovery and realize the full potential of their existing reserves.

Critical to achieving that objective is the ability to map levels, or depths, of oil-water and gas-liquid that continually change as oil and gas are withdrawn. Understanding these contact points helps operators assess their remaining reserves. For example, as oil is drained from the formation, subsequent reductions in pressure cause the gas to expand and move downward.

Additionally, logging tools that process and analyze data quickly and reliably can provide valuable information for improving recovery, such as how quickly and where oil and gas reserves are withdrawing from the formation vs. where the reservoir is not producing.

New technology development

In many cases the most cost-effective way to improve field economics is by expanding the performance envelope of existing technologies. Pulsed-neutron logging has long played an important role in helping producers find and manage oil and gas reserves. Expanding upon and improving this mature technology, the Raptor 2.0 cased-hole evaluation system makes it possible to characterize the reservoir beyond the initial phase of development through the life of the well. The enhanced sensor capabilities open the door for producers to gain a deeper and more precise understanding of the formation, obtain key measurements through large steel casing and multiple tubing strings, and process and analyze the resulting data.

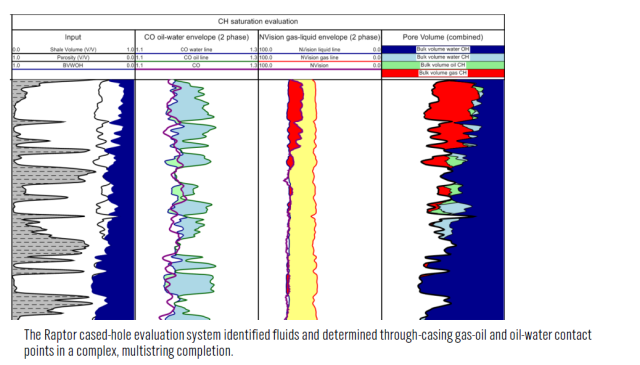

Designed to provide reservoir characterization after a well has been cased, the system combines a pulsed-neutron wireline logging device with advanced petrophysical workflows and reliable data processing and analysis to deliver accurate, actionable reservoir data, including high-fidelity oil-water and gas-liquid saturation measurements and through-casing identification of bypassed and previously unknown hydrocarbons by location, type and volume.

First five-detector array

The system provides the industry’s first five-detector array, which represents an exponential leap forward in pulsed-neutron technology, reliability and performance. By emitting controlled pulses of high-energy neutrons into the formation, the system is significantly more sensitive than traditional two-detector pulsed-neutron tools. Engineers can read deeper into the formation and better utilize existing information.

Four spectroscopic gamma ray sensors increase the gas-saturation measurement sensitivity by about 250% compared to conventional tools and provide dimensional oil-saturation measurements. This allows producers to increase their reservoir knowledge during completion, production and rejuvenation phases, ultimately identifying and recovering more oil in their reservoirs.

Data can be acquired through casing and tubing strings using various techniques. Once collected, the data are processed and analyzed by petrophysicists, who deploy an integrated response characterization, four-detector mixing, and transparent petrophysical processes and software. The measurements are analyzed using an integrated response characterization for each well, taking into account the combined effects of borehole size, casing, tubing, wellbore and annular fluids, lithology, and reservoir fluids.

The petrophysical analysis merges the measured data into a response envelope using a data interface that is intuitive, easy-to-use and transparent. The detailed analysis provides operators with actionable information to determine production strategies going forward.

Acquiring data in the field

Prior to its launch in June at the Society of Petrophysicists and Well Log Analysts Annual Symposium in Houston, the cased-hole evaluation system was tested and proven in more than 200 successful field runs worldwide. In one case, an operator in Malaysia successfully applied the system to determine a production strategy for improving oil recovery in a multiple-well project with challenging large-wellbore dual-string completions.

The operator sought to establish a production strategy for five directional wells in a mature oil-rim reservoir that features stacked shaly sands deposited in a deltaic environment and compartmentalized by faults.

The shallow sections of these wells were drilled with 12¼-in. boreholes at a deviation of up to 42 degrees. The wells had been completed with 95⁄8-in. casing and produced through single 4½-in. or dual 3½-in. tubing. The large borehole and multiple wide-diameter tubulars made for a complex wellbore environment that presented challenges in obtaining accurate measurements.

The key objectives were to determine gas-oil and oil-water contact points and inform production and infill drilling strategies to improve reservoir sweep and overall oil production. The operator also wanted to evaluate the shallower sands for hydrocarbon type since openhole logs in the play had been inconclusive.

After conducting a comprehensive prejob analysis, Weatherford wireline and petrophysical teams recommended using the cased-hole evaluation system in all five wells and acquiring formation evaluation data for each well using two techniques. The enhanced carbon- oxygen mode determines bypassed oil location and volume and identifies and corrects for carbonate lithology and cementation effects. The proprietary N-Vision mode determines bypassed natural gas location and volume and quantifies gas-liquid saturation in porosity ranges as low as 5%.

The tool logged through a range of fluids including gas, water, oil and completion fluid in the tubing and annuli and produced accurate response modeling even in the wells with dual-tubing completions. The team logged a cumulative 10,850 m (35,597 ft) with more than 148 pulsed-neutron generator operating hours. There were no lost-time incidents.

Analysis and results

After processing the data from all five wells, the petrophysical team created a complete saturation analysis for the field to provide actionable, precise information that gave the operator a roadmap for further development of the field. The N-Vision mode identified the gas-liquid contacts and quantified hydrocarbon gas saturation through the dual-string completions, even with gas in the tubing and annulus. The multidetector carbon-oxygen measurement provided accurate oil saturation data.

In addition to identifying gas-oil and oil-water contact points in all five wells, the system read deep into the formation through the casing and dual tubing strings to correctly identify the shallow sands as oil-bearing rather than gas-bearing. This information increased the oil reserve estimates and provided a detailed model of unproduced reserves to inform production and infill drilling strategies.

The versatile cased-hole evaluation system is suitable for any cased oil or gas well onshore or offshore and functions in both seawater and freshwater environments. The five-array tool also includes an enhanced sigma data acquisition technique that delivers water saturation data in porous, high-salinity formations and measures the diffusion-corrected formation sigma derived from four-detector mixing.

Recommended Reading

BKV Reaches FID, Forms Midstream Partnership for Eagle Ford CCS Project

2025-02-13 - If all required permits are secured, BKV’s CCS project in the Eagle Ford Shale will begin full operations in first-quarter 2026, the Barnett natural gas producer says.

California Resources Continues to Curb Emissions, This Time Using CCS for Cement

2025-03-04 - California Resources’ carbon management business Carbon TerraVault plans to break ground on its first CCS project in second-quarter 2025.

West Virginia Gains Authority for Class VI Wells for CCS

2025-02-18 - The state joins North Dakota, Wyoming and Louisiana in securing approval from the Environmental Protection Agency for Class VI well primacy for carbon capture and storage.

API’s Multi-Pronged Approach to Lower Carbon Operations

2025-01-28 - API has published nearly 100 standards addressing environmental performance and emissions reduction, which are constantly reviewed to support low carbon operations without compromising U.S. energy security.

Could EPA’s GHG Rule for Power Plants Give CCS a Boost?

2025-03-05 - Economics and policy are impacting the pace of carbon capture and storage project growth in the U.S. but some companies are pressing ahead.

Comments

Add new comment

This conversation is moderated according to Hart Energy community rules. Please read the rules before joining the discussion. If you’re experiencing any technical problems, please contact our customer care team.