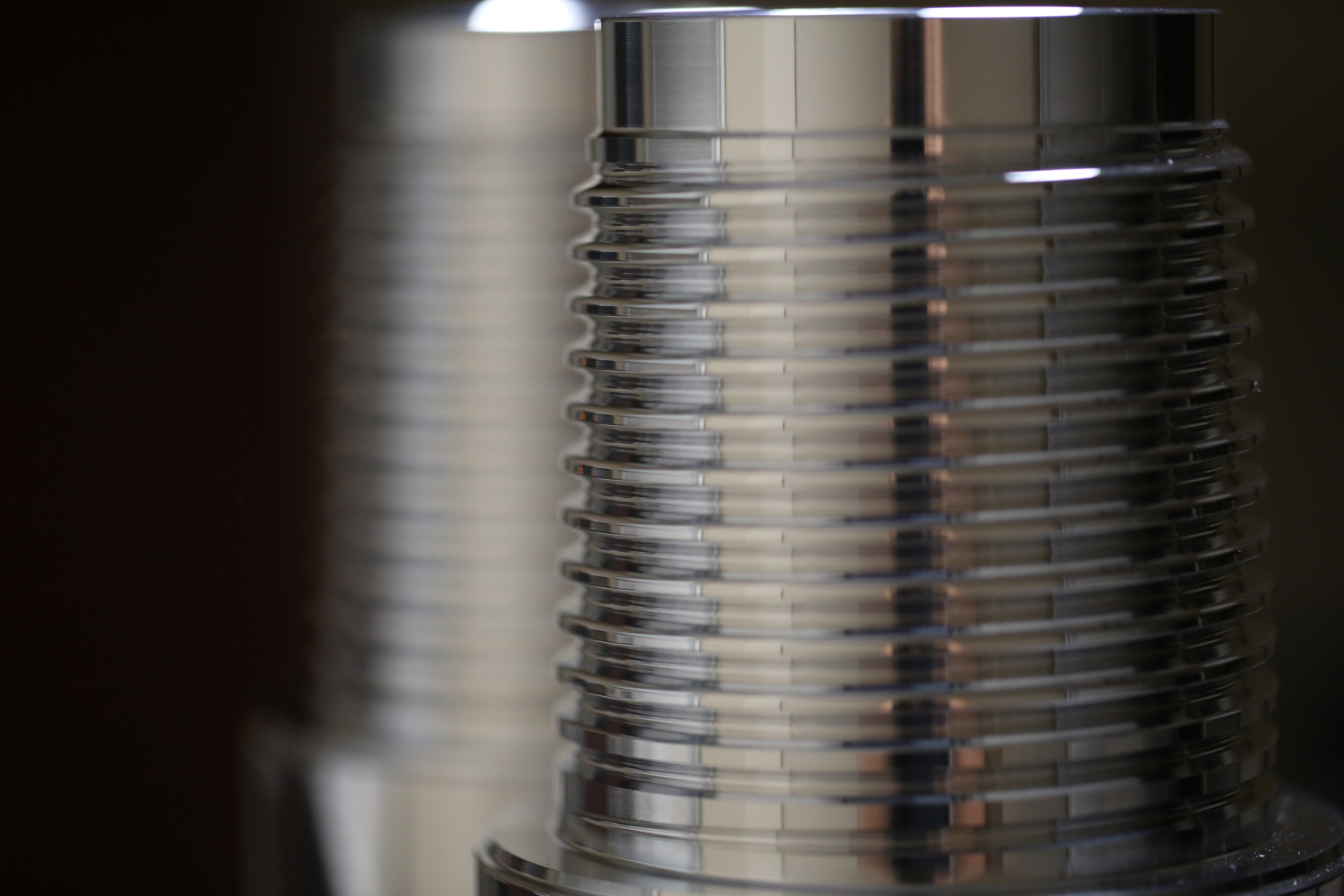

The Delta connection provides drillers more flexibility in the positioning of the iron roughneck due to a smaller tong-free area. (Source: NOV)

As the drilling landscape changes, an upturn in land factory drilling projects drives the need for efficient, high-performance products and technologies. NOV addressed the needs of this shifting market by developing the Delta line of rotary-shouldered drillpipe connections. These connections are stronger and more fatigue-resistant than other rotary-shoulder connections, and this allows a simplified threading procedure, which excludes the need for cold rolling, reducing the cost of maintenance and therefore lowering the total cost of ownership.

Performance-wise, the connection delivers on average 4% more torque than the XT connection. Using streamlined 130,000-psi tool joints, the Delta connection improves hydraulic performance by allowing the use of a larger-than-normal pipe body size. For example, 5½-in. drillpipe can be used to drill in the size of hole in which 5-in. drillpipe was previously used. This is made possible because the outside diameter of the tool joint is identical to the industry standard for 5-in. drillpipe (65⁄8 in.).

In addition to significant reduction in pressure losses, the connection also allows better borehole cleaning since fluid circulates at a higher velocity outside of the drillpipe. The stiffer pipe allows the drilling of a better quality hole.

In addition to significant reduction in pressure losses, the connection also allows better borehole cleaning since fluid circulates at a higher velocity outside of the drillpipe. The stiffer pipe allows the drilling of a better quality hole.

The modified geometry of the Delta connection engages more threads at stab-in. This minimizes stabbing damage while also evenly distributing stress.

The deeper stab-in also reduces the number of turns necessary to make up the connection, increasing efficiency and reducing wear on the threads.

Compared to similar products, the Delta connection requires 50% fewer turns from stab to makeup. The connection saves time in that it can be spun in as little as four seconds, while XT connections typically require eight seconds.

This decreased connection time translates to increased cost-effectiveness and ease of use on the rig floor. Ease of use is further improved by a reduction in the minimum required tong-gripping distance from the box face. When other connections require a 2-in. tong-free area to prevent egging of the box connection, the Delta connection only requires ½ in. of tong-free area, giving drillers more flexibility in the positioning of the iron roughneck.

Reduced cost of ownership

One of the main objectives while developing this connection was to reduce the cost of ownership. NOV determined the best way to achieve that goal is to keep the connection in service and reduce the frequency of repair. Multiple design choices contribute to maintaining the Delta connection—and the joint of drillpipe that carries it—in the field while drilling. First, wider field inspection tolerances reduce the need for frequent repairs without compromising the connection’s performance. Second, a tolerance for pitting in the root of the less critical threads was established. Besides these inspection criteria changes, the geometry of the new connection reduces the material loss by 30% for face-and-chase repair operations.

This allows more recuts using the same tool joint tong space. The reduction of the tong-free area on the tool joint results in increased room for recuts given the same tool joint length. The total refacing amount has been increased by 50%, allowing additional refacing to take place before a recut is needed.

Best practices were developed by the company for its licensees in the shop environment for these recuts. These practices will result in less than a 1-in. loss on pin or box for a full face-and-chase repair. The connection also has the lowest royalty on repair services across all of NOV’s double-shoulder connections. The Tuboscope Business Unit within NOV Wellbore Technologies further supports the connection with reduced repair rates to pipe owners and the option to include the TracID radio frequency identification-based tagging and inventory management system as part of the base configuration for the pipe connection. In support of the Delta connection NOV developed rig-ready upgrades such as the TDS-11SAH top drive, ST-80X iron roughneck and a 7,500-psi pump.

Before its introduction to market the Delta connection underwent extensive testing at NOV’s research and technology development center, with early results demonstrating that the new connection made up twice as fast as its predecessor. During testing, damage was minimal and was primarily related to handling. Generally, only refacing was required to repair the damage.

Case studies

The first string of drillpipe with the Delta connection was used to drill a well in the Permian Basin and was the subject of intense scrutiny. This initial drilling job was very successful, and the 5½-in. drillpipe with the Delta 544 connection delivered as expected. The drilling project finished ahead of schedule, and the hole quality of this longest lateral for the operator in this field was excellent, with smooth running of the casing string. A post-use visual inspection of the connections was conducted and confi rmed that the Delta string was in excellent condition after drilling the well. The rental string was retained by the operator and will be used again to drill another pad.

Two other strings with Delta 544 connections were deployed in April 2017, one in the Gulf of Mexico (GoM) and another on a land rig in West Texas. Once again, the customers found the product easy to use, and the field service personnel who were dispatched to these rig sites could see that drillers quickly became comfortable with the new connection.

In June the different sizes of the Delta connections were used on land and offshore. The Delta 425 on 4½-in. drillpipe was used in the GoM, South Texas and the Bakken Shale. Field service staff went to the rig site and saw the same pattern repeated: ease of use, low damage rates and satisfied end users. Drilling crews were at ease with the product and rapidly embraced its use. In addition, a string has been deployed to the Middle East for testing.

In all cases, the condition of the connection was visually evaluated after use, and so far none have required rethreading. This is extremely encouraging to the early users, and NOV looks forward to gathering more data once these strings have received a full visual and dimensional inspection of the Delta connections.

Have a story idea for Shale Solutions? This feature highlights technologies and techniques that are helping shale players overcome their operating challenges. Submit your story ideas to Group Managing Editor Jo Ann Davy at jdavy@hartenergy.com.

Recommended Reading

Manufacturers Urge FERC to Study Gas Pipeline Capacity Needs

2025-02-04 - Heavy industry is the first to be impacted when there is inadequate supply of natural gas, the Industrial Energy Consumers of America (IECA) argued in a letter to federal regulators.

Building Pipelines in Blue States Requires Coalition of the Unusual

2025-03-13 - Former politicians say winning permits for pipelines in Democratic-leaning states requires uniting a diverse set of stakeholders—from civil rights activists to West Texas oilmen.

Williams Starts Work on Overthrust Pipeline Expansion

2025-03-03 - The extra capacity from the MountainWest Overthrust Pipeline expansion project will help deliver natural gas to the West Coast.

Industry Players Get Laser Focused on Emissions Reduction

2025-01-16 - Faced with progressively stringent requirements, companies are seeking methane monitoring technologies that make compliance easier.

Trump Fires Off Energy Executive Orders on Alaska, LNG, EVs

2025-01-21 - President Donald Trump opened his term with a flurry of executive orders, many reversing the Biden administration’s policies on LNG permitting, the Paris Agreement and drilling in Alaska.

Comments

Add new comment

This conversation is moderated according to Hart Energy community rules. Please read the rules before joining the discussion. If you’re experiencing any technical problems, please contact our customer care team.