In 2014 William Jacob Management Inc. (WJM) released the modular offshore rig facility (MORF) design to help slash deployment costs and improve speed to market for upstream operations. The MORF is a copyrighted design for a 3,000-hp modular drilling facility and is the first of its kind in size and configuration to be operational in the Gulf of Mexico (GoM). The fully detailed design has undergone several refinements and further development since its initial conception, such as efforts to simplify methods of installation and interconnection. WJM engineers and designers continue to refine the MORF’s design, drawing from lessons learned after each project for which it is deployed.

Reducing time, costs

Developed initially for a national oil company with a major presence in the GoM, the MORF’s design program was driven by the client’s demand for improved cost performance across its offshore operations. Essentially, the challenge was to develop an offshore modular rig facility that would bring down deployment costs and increase the speed of installation and startup for the client.

The design team opted to think small to make a big impact. The design engineers deliberately downsized the individual modules so they could function like a set of interlocking building blocks delivered by the client’s service fleet and lifted into place by a “leapfrog” crane system from the platform and rig facility, streamlining installation. This solution enabled the modular rig to be configured for drilling and integrated production below while providing significant cost savings in deployment as a result of not having to use an expensive heavy-lift vessel.

Elements of the MORF design

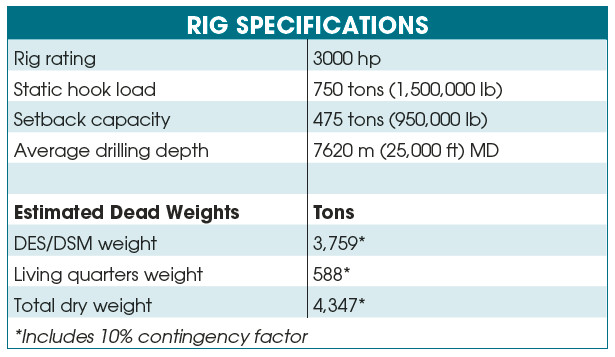

The rig has three main modules: the drilling equipment set (DES), the drilling support module (DSM) and the living quarters facility (LQF). The DES has the capacity to access 15 wells arranged in a three-by-five matrix, which can easily be adjusted to suit most platform configurations, and is capable of drilling wells up to 7,620 m (25,000 ft). The DSM is equipped with a pair of 100-ton rig cranes that streamline installation. The DSM’s main platform cranes are used to install the remaining MORF modules after installation and startup and backload the temporary installation cranes. The LQF has modular capacity for 100 personnel.

The design premise is to tow barges containing the various modules to the platform site. The first barge/supply vessel contains the erection crew plus small hoisting devices that are man-handled/rigged onto the main platform deck. With the aid of stiff-legs, the temporary installation crane is lifted and assembled into place.

The modules containing the rig cranes are installed using the temporary leapfrog crane package, and once the rig cranes are operational, the installation is then completed using the rig’s own cranes. This strategy effectively eliminates the need to contract a costly lift barge.

Further barges are used to deliver larger module structures to the platform. These larger modules are installed using the two in-place 100-ton rig cranes. Due to their compact size, the modules can be delivered using typical service vessels and/or offshore supply vessels.

The modular design target was an average outfitting weight of about 50 tons. In an effort to reduce construction cost and assembly time, WJM is using the lifting lug and stabbing guide as an integral part of the in-place MORF securing system. The use of a module securing plate, installed over the lifting lugs during assembly at all column interface points, allows no additional fabrication needed for lateral support. Vertical lift is addressed through a compression clamping assembly, which is easily installed from the module being secured.

A considerable investment was made by WJM with regard to the electrical and piping interconnects between the modules. The effort focused on making these interconnects as efficient to execute as possible, allowing the rigup and rig-down durations to be minimized. WJM engineers and designers reviewed piping and electrical connection applications in various industries, which resulted in a number of opportunities to improve the connect/disconnect approach in the MORF design. One development included a database and a tracking system for all of the piping spools and electrical plugs. Another was the use of quick-connect junction boxes to improve the reliability of the electrical connections considering multiple “make and break” of connections over the life of the drilling unit. Due to the small modular concept and the quick interlocking philosophy, the configuration can be modified to suit the client’s particular requirements, such as removal of the living quarters package and inclusion of extra equipment or storage. The initial concept was based on a specific client requirement for manual tubular handling. This also can be upgraded to a semiautomated system to include horizontal conveyor and knuckleboom crane handling systems.

MORF specifications

The MORF design takes into account collection, storage and transportation (to shore base) of all drilling cuttings, resulting in zero discharge. It also has been designed to comply with all applicable codes and standards and primarily designed to comply with multiple functions (Table 1).

Thanks to their compact size, the modules can be delivered using the client’s service fleet, then assembled using a combination of crane systems. The design of modules and interconnects provides flexibility for a wide range of platforms and environments. It also enables efficient decommissioning and redeployment for the next drilling program by way of the small modular lifts.

With the shortage and associated expense of large derrick barges throughout the industry since 2014, many of WJM’s clients were encouraged to turn to the MORF to reduce costs in their offshore developments. Due to the financial restraints imposed within the industry since early 2015, a more efficient and economical way of drilling or continuing to drill offshore needs to be addressed. The MORF concept is a more cost-effective way of addressing multiple platform drilling and workover requirements, which fits well with the demands of the current industry climate. The MORF, therefore, is not just a drilling unit but also a strategic asset.

Visit williamjacob.com/html/WJM_Solutions.html to view an animated MORF installation sequence and a detailed specification sheet.

Recommended Reading

Diamondback Energy Closes $4.1B Double Eagle IV Acquisition

2025-04-02 - Diamondback Energy Inc. closed on its approximately $4.1 billion deal to buy EnCap Investments’ Double Eagle IV, adding approximately 40,000 net acres in the Midland Basin to its portfolio.

SM Energy Marries Wildcatting and Analytics in the Oil Patch

2025-04-01 - As E&P SM Energy explores in Texas and Utah, Herb Vogel’s approach is far from a Hail Mary.

Waterous Raises $1B PE Fund for Canadian Oil, Gas Investments

2025-04-01 - Waterous Energy Fund (WEF) raised US$1 billion for its third fund and backed oil sands producer Greenfire Resources.

Williams Commissions Two NatGas Projects to Expand Transco Network

2025-04-01 - Midstream company Williams Cos. added to its network capacity in the southern U.S. with the commissioning of the Southeast Energy Connector and the Texas to Louisiana Energy Pathway.

CenterPoint Energy Completes NatGas Pipeline Sale to Bernhard

2025-04-01 - CenterPoint Energy Inc. has closed on a sale of natural gas distribution utilities in Louisiana and Mississippi to Bernhard Capital Partners.

Comments

Add new comment

This conversation is moderated according to Hart Energy community rules. Please read the rules before joining the discussion. If you’re experiencing any technical problems, please contact our customer care team.