Seismic exploration has long been known to work in remote regions of the globe. However, frontier exploration can be defined not necessarily as a geographical anomaly but more generally as a region that has had limited exploration. This can mean anything from distant jungles to densely populated urban areas, but a common theme is that access by seismic crews has previously been limited or restricted. Fewer regions of the earth qualify, but the evolving technology of seismic exploration will play a critical role in opening up new and unexplored frontier areas.

Advancements in seismic equipment make projects in sensitive or operationally challenging locations more practical and in some cases economically feasible. Modern seismic equipment is lightweight and low-impact; cableless systems can be deployed in any environment and are nearly invisible to local populations or indigenous wildlife. Small vibrators pack a big punch but can access challenging terrain with discrete operations, which makes this technology combination ideal for the

remaining frontiers.

Cableless seismic equipment

The utilization of cableless equipment for collecting seismic data has grown steadily since the early 2000s. Cableless equipment has all but totally replaced cabled seismic equipment as the method for collecting data in North America. This evolutionary change was driven by two main factors. The primary reason is the availability of modern, cost-effective and reliable technology that allows the operational cost of seismic projects to be comprehensively controlled. The second reason is because modern cableless systems include remotely deployable nodes, each of which is essentially a standalone recording system. By virtue of this architecture, the systems are fully scalable and can be deployed at any group interval and in virtually

any setting where physical access is possible. It is this flexibility of equipment that has made the concept popular with contractors and explorationists alike.

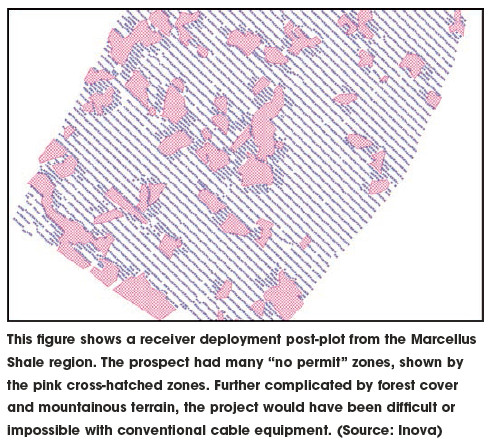

Many prospective areas have not been thoroughly explored with seismic because access or terrain was difficult. Examples of this type of area can be found in the Marcellus Shale region of the northeastern U.S. The region is mountainous and is covered by dense forest in areas. Land ownership is fractioned into many small tracts, making permitting very difficult. Land owners are sensitive to the often intrusive nature of oil and gas exploration; however, cableless systems have found a strong following in this area because crews can work with light vehicles and, once deployed, the equipment is practically invisible to the local population. Seismic exploration can be carried out with little or no lasting impact on the land or its inhabitants. Issues related to battery life and equipment tampering or thefts are now considered manageable or even minor to the point that cableless equipment has proven to be highly reliable; in most cases 99% trace yields or better are expected and achieved.

Cableless equipment also allows full flexibility in survey design. Geophysicists are no longer constrained by conventional geometry spacing dictated by cable lengths or even by conventional geometry lines. Trends toward more grid-based receiver geometries are proving practical and effective.

Small-sized vibrators

Contrary to the trends of the last decades, where vibrators have steadily increased in size, small vibrators have become serious contributors to seismic exploration in many areas. Preferred because of their small footprint, tight turning radius and low environmental impact, they can be found on every continent of the globe. Even though they have small form factor, they can now be purchased in configurations as heavy as 34,000 lb, but probably the most appealing virtue of the modern small-sized vibrators is their geophysical performance. They have successfully swept from 1.5 Hz up to as high as 250 Hz in production seismic shooting. Tests have shown that frequencies as high as 280 Hz can be observed at depths of 2,286 m (7,500 ft) in vertical seismic profiling operations. In the deserts of the Middle East 26,000-lb UniVibs have worked on the same projects as 80,000-lb vibrators, accessing treacherous sabkha areas where the heavier vibrators could not go. The resultant data when processed are of similar quality when blended.

They are also easier to transport, can fit into a standard shipping container (using modified wheels) and are easier to permit in urban areas or zones where there are concerns about noise or excessive ground motion. Like their bigger cousins, the small-sized vibrator can run custom sweeps and use high-productivity operational methods.

Lowest impact seismic, no geophysical compromise The combination of highly flexible cableless equipment and small-sized vibrators adds up to the very lowest impact seismic acquisition with little or no compromise on the geophysical qualities of the project. Lightweight, low-impact equipment combined with careful operational management has been the key to success in national parks, large cities and many other areas with restricted access.

The small-sized vibrator has been shown to get good reflectivity at targets as deep as 3,048 m (10,000 ft) in areas like the Georgia Rift Basin and Oman. The small size and light footprint of the vibrators reduce surface damage and, in areas where line cutting is required, they reduce the degree of cutting since the vibrator can maneuver a cut line as narrow as 4 m (13 ft).

In urban settings the cableless equipment can be hidden or buried when it is deployed, making it unobtrusive to the local population and reducing theft and tampering. The combination of these two technologies is ideal when low-impact seismic is a requirement, as is often the case in frontier seismic exploration.

Looking forward, since cableless systems are easily scalable, geometries with high-density designs can be envisaged. Dense receiver spreads with high trace density and tight sampling intervals have superior properties to sparser geometries and have the capability to significantly improve noise attenuation and improve reservoir imaging while maintaining the critical goals of low-cost and low-impact acquisition.

Recommended Reading

Hibernia IV Joins Dawson Dean Wildcatting Alongside EOG, SM, Birch

2025-01-30 - Hibernia IV is among a handful of wildcatters—including EOG Resources, SM Energy and Birch Resources—exploring the Dean sandstone near the Dawson-Martin county line, state records show.

Shale Outlook: E&Ps Making More U-Turn Laterals, Problem-Free

2025-01-09 - Of the more than 70 horseshoe wells drilled to date, half came in the first nine months of 2024 as operators found 2-mile, single-section laterals more economic than a pair of 1-mile straight holes.

E&Ps Pivot from the Pricey Permian

2025-02-01 - SM Energy, Ovintiv and Devon Energy were rumored to be hunting for Permian M&A—but they ultimately inked deals in cheaper basins. Experts say it’s a trend to watch as producers shrug off high Permian prices for runway in the Williston, Eagle Ford, the Uinta and the Montney.

On The Market This Week (Jan. 6, 2025)

2025-01-10 - Here is a roundup of listings marketed by select E&Ps during the week of Jan. 6.

Formentera Joins EOG in Wildcatting South Texas’ Oily Pearsall Pay

2025-01-22 - Known in the past as a “heartbreak shale,” Formentera Partners is counting on bigger completions and longer laterals to crack the Pearsall code, Managing Partner Bryan Sheffield said. EOG Resources is also exploring the shale.

Comments

Add new comment

This conversation is moderated according to Hart Energy community rules. Please read the rules before joining the discussion. If you’re experiencing any technical problems, please contact our customer care team.