The Society of Petroleum Engineers (SPE) is hosting its Annual Technical Conference and Exhibition (ATCE) Oct. 9-11 in San Antonio, Texas.

“For more than 90 years, ATCE has been the meeting of choice for SPE’s members and other professionals seeking education on current and future technologies that help find and produce hydrocarbons faster, more efficiently, safer and more cost-effectively,” the conference website stated.

The following is a sampling of some of the latest technologies that will be showcased at SPE ATCE 2017.

Editor’s note: The copy herein is contributed from service companies and does not reflect the opinions of Hart Energy.

Data analysis software enhances financial reporting

Aclaro Softworks Inc.’s petroLook is a web-based business intelligence solution used by E&P companies to manage reserves, budgeting and planning. The foundation of petroLook’s value to producers is its ability to gather data from multiple source systems, giving the richest possible pool of data for informed decisionmaking. petroLook is a comprehensive data analysis tool for budgeting, planning and resourcing. It’s highly configurable and scalable, with extensive reporting capabilities, and can be tailored to the needs of companies of any size. petroLook Reserves (available pre-configured or for Enterprise) lets companies have visibility into their resource positions. The system is an accurate, secure and auditable platform that enables a flexible approval process, automated reconciliation and internal and external reporting. petroLook Portfolio Advisor is an oil and gas software that offers fully constrained multi-objective optimization. This technology can be leveraged to align portfolio decisions with corporate strategic goals and acquisition and divesture activity. aclaro.com

Polymer system enhances proppant placement

Polymer system enhances proppant placement

Binder Science has developed a viscoelastic polymer system designed to enhance proppant placement. Proppant transport is categorized as either heterogeneous or homogeneous. Heterogeneous slurries settle and stratify, with coarser particles at the bottom of the flow area. This process, referred to in the industry as “dune and push,” repeats itself until plugging or screenout in the formation occurs. At that point sand placement ends and flushing begins. Frequently, screenout occurs sooner than desired, and the sand placement falls short of the fracture design target. Binder’s copolymer rheology system is designed to keep proppant in the homogeneous flow regime, where proppant does not settle and screenout does not occur. The result of this placement method is significantly increased crude production. binder-science.com

Tool reduces pipe friction pressure up to 85%

BJ Services will be showcasing its ThinFrac MP friction reducer. The tool is designed for maximum regained permeability. The technology has been proven in North American shale plays to significantly increase production. Used in slickwater, hybrid and foam fracturing operations, this synthetic polymer develops instantaneous viscosity, providing superior proppant transport when and where it is needed. Its rapid hydration capability reduces pipe friction pressure by as much as 85% when compared to conventional fluids. The enhanced polymer has been engineered to contain oxidizable linkages along its backbone, allowing a clean, efficient break with little to no formation or proppant pack damage. New generations of the fluid further improve viscosity and salt tolerance. ThinFrac MP is part of the company’s family of linear gels that improve proppant transport and reduce friction to create large complex fracture networks. bjservices.com

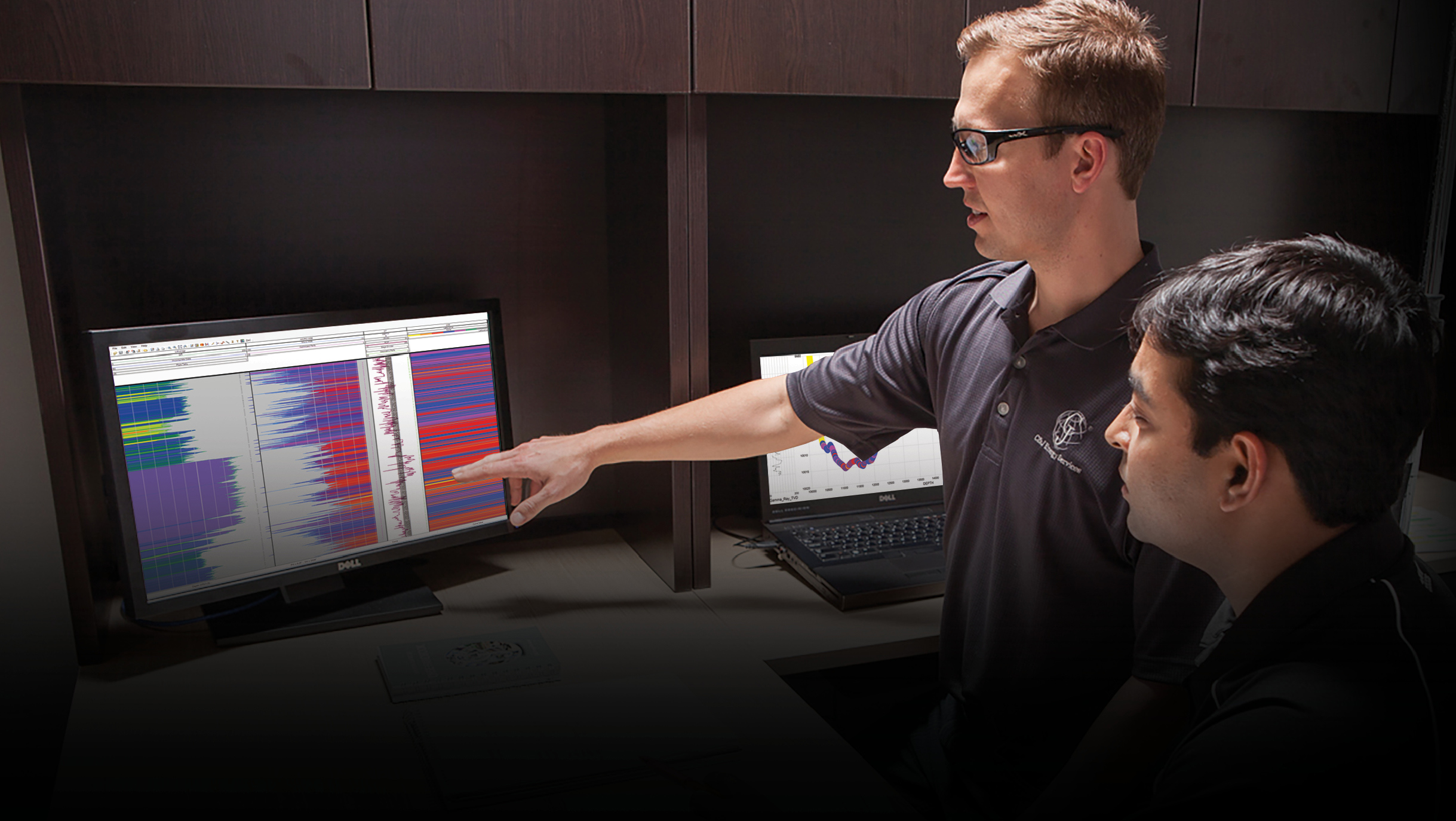

Get to know your lateral

Get to know your lateral

C&J Energy Services will showcase the LateralScience engineered-completion service. The LateralScience approach leverages commonly available data collected during drilling of the well, which is then used to optimize horizontal completions. Because these data are already on hand, operators can avoid the considerable data-collection expense normally associated with assessing horizontal wellbores. For operators already using other methods to engineer completions, this new technology offers a solution that is more convenient and orders of magnitude less expensive. This means operators can now afford to optimize every horizontal well they complete. For operators still executing geometric completion designs, LateralScience has been demonstrated to increase production an average of 30%. In addition, the facies logs included in the LateralScience deliverable package benefit users by helping them understand differences in reservoir characteristics between wells. This provides guidance to improve the reservoir development strategy across the entire field. cjenergy.com

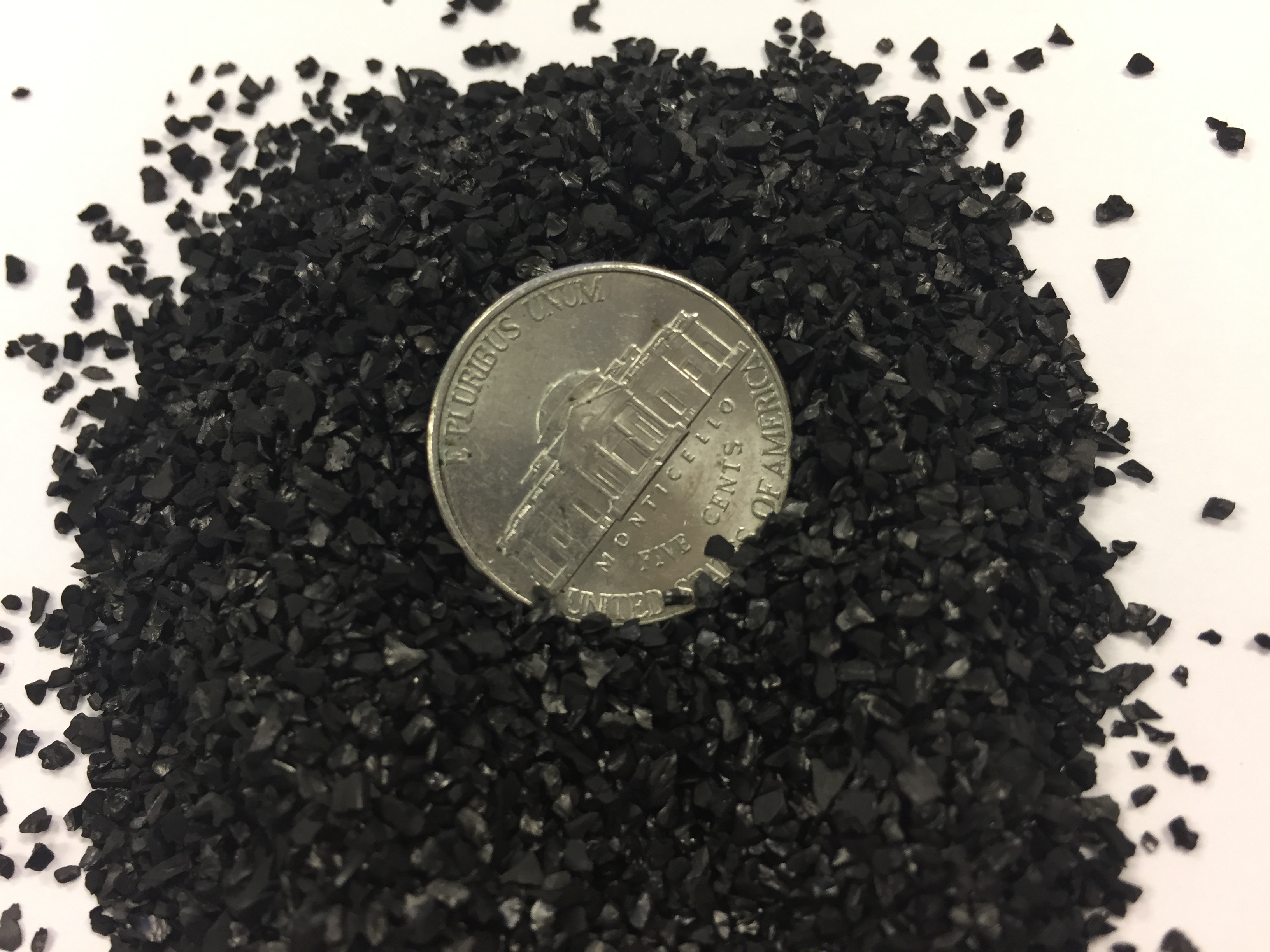

Cleaner, more conductive proppant pack

Cleaner, more conductive proppant pack

Calfrac introduced CalVisc in the Williston Basin in 2014. Developed as an alternative to traditional crosslinked fluid systems, CalVisc is a polyacrylamide-based (or friction reducer) fracturing system designed to deliver a cleaner, more conductive proppant pack. The system offers a shear thinning characteristic that results in greater viscosities at low shear rates. With relatively low chemical loadings, CalVisc generates significant viscosity, allowing fracture treatments to be placed with the same sand design previously used with crosslink guar systems. CalVisc carries up to 5 ppg sand through about a 3,000-m (10,000-ft) lateral wellbore with viscosities of 15 cp to 30 cp at 511 sec-1. It provides higher viscosity while greatly reducing formation damage; reduces friction, allowing proppant placement at lower pressures; and drastically reduces water requirements when compared to basic slickwater systems. CalVisc is a disruptive fracturing fluid technology that helps users make better wells at lower cost. calfrac.com

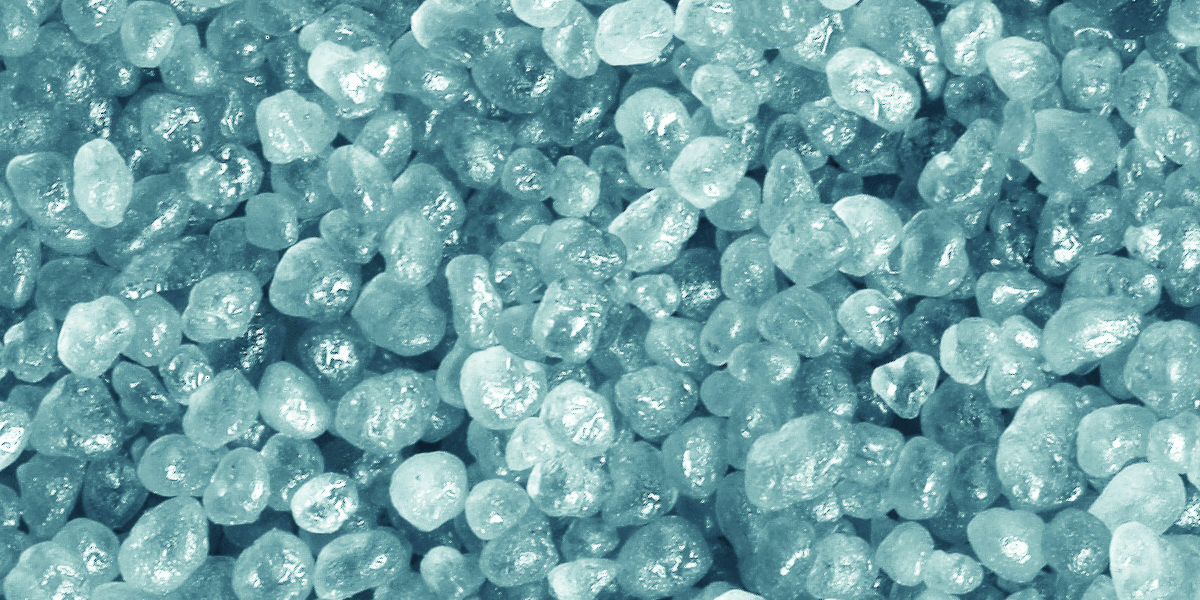

Increasing EUR from slickwater fracturing operations

CARBO will be showcasing its new CARBOAIR high-transport ultra low-density ceramic proppant technology. Slickwater fracturing fluid systems are finding increasing applications in unconventional reservoirs to accommodate evolving fracture stimulation designs and cost structures. However, proppant transport and placement in these treatments present challenges for stimulation design optimization and effectiveness due to their low viscosity, which negatively impacts proppant carrying capacity. This can lead to lower fracture conductivity since slickwater treatments are limited in proppant maximum concentration. CARBOAIR has chemically engineered internal porosity and is designed to increase production and EUR from slickwater fracturing operations. The technology has an apparent specific gravity about 25% lower than sand. The technology also delivers increased propped fracture height and length over a range of applications to maximize effective fracture contact area and conductivity. CARBOAIR can increase production across various formations by delivering improved proppant transport, propped fracture geometry (length and height), fracture conductivity and reservoir contact area in comparison with conventional sand. carboceramics.com

Methodology relates organic porosity to TOC with triple-combo suite

By using triple-combo logs, it is possible to quantify clay porosity, total organic carbon (TOC), effective porosity (inorganic) and effective porosity (organic). Organic porosity is formed during thermal maturation of the TOC. Comparisons can be made between organic porosity and TOC. In a comparison of Bakken and Mowry data, it appears that the Bakken has significantly greater organic porosity development. digitalformation.com

Partnership results in tool to help reduce overall rod cycles

Partnership results in tool to help reduce overall rod cycles

To provide a holistic approach to the most challenging rod lift applications, Dover Artificial Lift and Liberty Lift Solutions have strengthened their longstanding relationship. Dover Artificial Lift includes Norris Rods and Harbison Fischer Pumps along with Energy Automation variable-speed drive controllers and smart chemical management.

The Liberty Lift Long Stroke (XL) Pumping Unit offers an ideal means of managing production cost at an optimum level. The XL Unit provides a high-performance rugged design, greater efficiency and proven reliability. Its extra-long stroke lengths of 306 in. and 366 in. allow the rod pump a slower travel time to provide more complete fillage and higher volumetric efficiency.

The XL Unit is well-suited for work in deviated, deep or high-volume wells as an optimal alternative to other lift forms. doverals.com

Water clarifiers ready to use with no need for inversion during application

Water clarifiers ready to use with no need for inversion during application

Dow Chemical Co.’s ROMAX 6011 and ROMAX 9011 are the newest water clarifiers offered by the company. These products are formulated to be ready to use with no need for inversion during application and feature anionic acrylic latex as an active ingredient. ROMAX 9011, the freeze-protected water clarifier, withstands cold temperatures down to -40 C (-40 F). Acrylic latex was developed during an R&D effort that focused on the optimization of water clarifiers for tough-to-resolve emulsions through systematic analysis of statistically designed products. For more information on Dow’s full portfolio of products for oil and gas, visit booth 1177. dowatce.com

Platform identifies refractured wells worldwide

Refractures are increasingly becoming a more important component of long-term planning. But what really makes a successful refracture? Drillinginfo and DI Refrac Analysis provide an easy-to-use step-by-step guide to identifying refractured wells, understanding how they were completed and their impact on production and pinpointing the most promising candidates for refractures. This platform enables operators to find the information needed to maximize production, value assets and companies; identify best practices in refracturing; and conduct competitive analysis. info.drillinginfo.com

Pinpoint casing defects and metal corrosion

Pinpoint casing defects and metal corrosion

The Halliburton Electromagnetic Pipe Xaminer V (EPX V) tool allows operators to more accurately pinpoint casing defects and metal corrosion to help reduce nonproductive rig time. It has the ability to quantify metal integrity in one to five concentric pipes during a single trip in the hole so that users can determine a solution quickly. The EPX V tool operates via mono-conductor wireline, enabling more efficient wellsite operations through the use of cased-hole service equipment. Halliburton’s BaraShale Lite water-based drilling fluid is engineered to drill more efficiently in fields that contain salt formations with low fracture gradients such as in the Permian Basin. The system contains a proprietary emulsifier that tightly combines the base fluid, which comprises brine to prevent salt washout and oil to lighten the mud weight. The result is a fluid system that prevents lost circulation and washout while minimizing dilution and waste volumes. halliburton.com

Proppant helps stimulate microfractures

Proppant helps stimulate microfractures

Uncoated 100-mesh proppants are useful to stimulate microfractures within the reservoir and extend propped fracture length. However, initial well production is often followed by a steep decline. This can be attributed to proppant flowback and significant fines generation due to proppant failure. Rearrangement of the proppant pack also can occur, leading to reduced propped fracture width. Hexion’s kRT 100 proppant is an economical, curable resin-coated 100 mesh sand. This proppant supports the intended use of 100-mesh sand within the fracture network, while the resin coating bonds the proppants together in the fractures to keep the grains from shifting or rearranging. The resin coating also provides all of the traditional benefits of a resin-coated sand such as proppant flowback control and fewer proppant fines. hexionfracline.com

Tankers transport hazardous and nonhazardous liquid materials

Tankers transport hazardous and nonhazardous liquid materials

To meet today’s challenges in transporting both hazardous and nonhazardous liquid materials, Hoover Ferguson has developed an extensive line of containers approved to International Standards Organization (ISO) standards: stainless steel ISO and IMO (Institute for Marketecology) certified tank containers and UN packaging-certified portable tanks. The ISO tanks are equipped with insulation, steam trace heating and cooling capabilities, and optional safety features such as fall protection with extended safety ladders and custom step fenders and handrails on custom drop-deck chassis. An online container and asset management portal, Liquitrac, leverages the latest barcode technology in combination with an app and smartphone to provide asset tracking, document storage, reporting and level monitoring capabilities. Documentation can be stored, uploaded and retrieved for cleaning, repairs, regulatory compliance and more. Real-time analytics and advanced tracking technologies accompany customizable alerts and reports, which users can receive on demand. Use of the portal delivers increased visibility on assets, enabling quicker and more informed decision-making and greater control over costs. hooverferguson.com

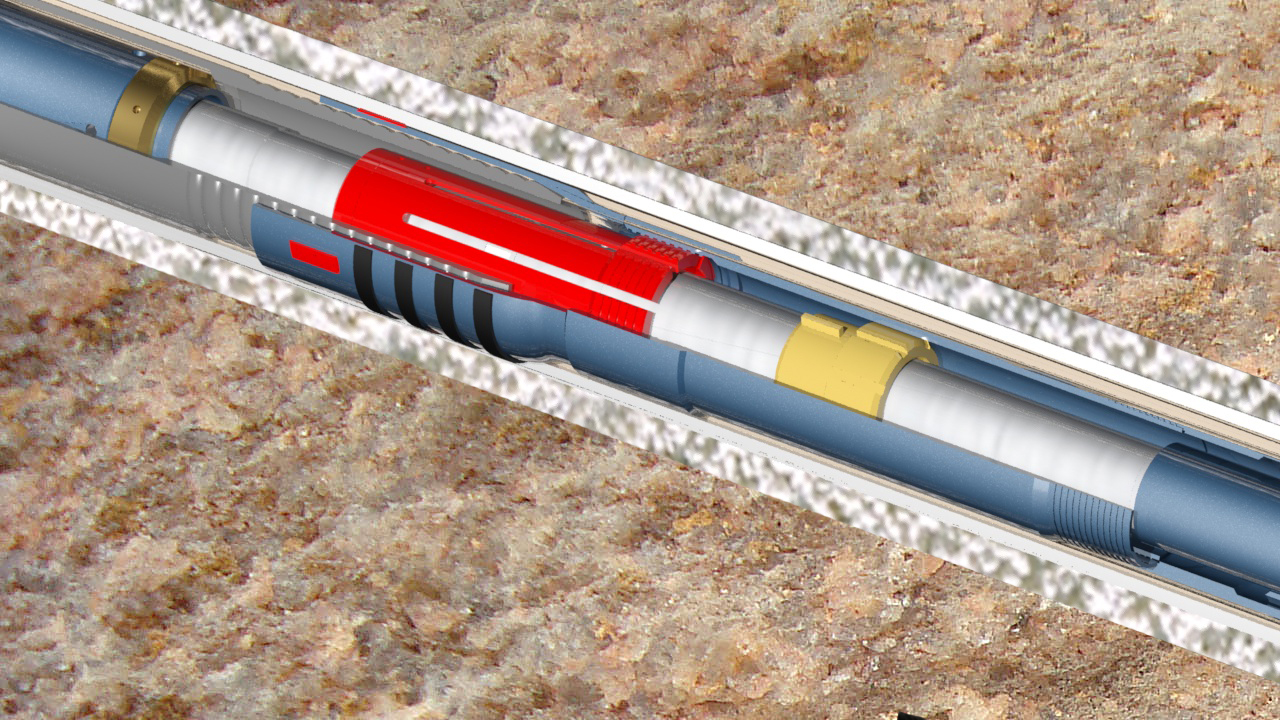

Perforating system advances safety, stage efficiency and success rates

Hunting reported that operators using its Titan Division’s H-1 perforating system have performed more than 38,400 runs since introduction last year without any safety-related incidents and with fewer personnel. The H-1 system provides operators with an advanced select fire perforating gun system that has no wires from gun to gun, fewer connections, no exposed detonating cords and real-time shot verification. The H-1 perforating system addressed common causes of misruns by eliminating the potential for pinches or nicks in the lead wire, reducing the risk of O-ring seal-point failures, and providing more precise operational confirmation downhole on the gun string’s status, which reduces lost time to misruns. Eighteen pounds of loaded weight per gun also was eliminated, and the tool string was shortened to allow more guns to be run per stage. One service company/operator completed more than 3,300 stages totaling more than 16,000 H-1 guns with zero failures. By comparison, a successful run rate for conventional gun systems is one failure for every 200 stages. The service company/operator also reported an 80% decrease in gun loading time, 66% elimination of seal connections and the replacement of three wire connections with the H-1 system’s simple cartridge insert. hunting-intl.com

Platform empowers digital transformation

Platform empowers digital transformation

IVAAP is the cloud-enabled platform that will empower E&P companies to optimize performance and unlock significant value. IVAAP is the first digital visualization and analytics web platform that empowers digital transformation in E&P. The platform accelerates development of web-based data visualization and analysis solutions in geology. geophysics, drilling and production by using microservices technology, a lightweight and component- based architecture that connects to multiple data sources simultaneously. Making operational and business decisions requires comprehensive analysis of complex data from many sources. IVAAP was designed to allow operators and service companies to tailor the system for their specific needs; extend functionality; and plug in their own workflow and IP by monitoring drilling, combining well log data with directional information, visualizing schematics and tracking key performance indicators. int.com

System allows test in the direction of flow to be carried out

System allows test in the direction of flow to be carried out

Testing of any wellbore barriers, including temporary mechanical wireline plugs and permanent installed barriers based either on cement or any other material, should always be carried out in the direction of flow. A newly developed concept of the Barrier Verification System allows oil and gas operators to do this. The concept allows the creation of negative pressure between the installed barriers and a verifying device. In doing so, a test in the direction of flow can be carried out. The Barrier Verification System can then document the setting of the installed barrier, pressure test, downhole temperature and loads that the barrier is exposed to. The overall time spent testing the barrier has been significantly reduced along with stress exposed to the wellbore that would typically be seen during a conventional positive pressure test. The service is available across industry standard tubing/casing weights. http://www.interwell.com/

New teaching methods include rig installation and operations training

New teaching methods include rig installation and operations training

Kerui Group is promoting its drilling rig and digital immersion teaching system, which adopts a combination of operating real drilling rigs and the added safety of digital simulation. The system includes rig installation and operations training. Kerui is able to show the installation processes of rig parts through 3-D and interactive animations, including environmental sounds, alarm systems, real-time voice simulations, etc. Kerui’s teaching drilling rig can provide training of the rig installation process, round-tripping, rig accessories operation, downhole accidents and complex situations for students. The training rig uses the company’s advanced self-lifting mast and boxon- box type substructure. It is also equipped with a traintype rig transportation system, which can move the entire rig integrally. Different from the classical classroom screen projection teaching mode, the teaching drilling rig is a new teaching method that adopts the latest 3-D simulation technology as well as virtual reality. keruigroup.com

Real-time microseismic completions evaluation analysis

Real-time microseismic completions evaluation analysis

Real-time microseismic monitoring from anywhere in the world has allowed operators to make better and more economic decisions as they see the impact of hydraulic stimulation on the reservoir in real time. MicroSeismic has released its next generation of real-time monitoring, allowing for on-the-spot completions evaluation. For realtime fracture modeling, users can determine fracture size and orientation as data are acquired, allowing a realistic real-time visualization of the fracture treatment. For dynamic stimulated reservoir volume (SRV) estimation, users can model fracture intensity and induced permeability to allow real-time analysis of SRV and productive SRV. For end-of-stage EUR and drainage estimation, users can generate permeability models and type curves for rapid assessment of induced drainage area and overall productivity. In addition, for rapid stress analysis users can get detailed moment tensor data for analysis of the interaction of the stress regime and the treatment. By having the ability to change completions activities faster and with more confidence, operators will have the opportunity to increase productivity and EUR. microseismic.com

Drilling tools designed to increase efficiency

Drilling tools designed to increase efficiency

Among NOV’s ReedHycalog offerings, the VectorEDGE rotary steerable system (RSS) is the first RSS tool designed specifically for performance drilling of vertical and lateral sections in unconventional wells. This cost-effective and fit-for-purpose tool can be run in conjunction with a mud motor and enables directional drillers to achieve higher drilling performance in vertical sections and extended laterals while maintaining borehole quality and accuracy. The Tektonic drillbit platform offers a comprehensive solution to drilling challenges. By fusing the high durability and toughness of FuseTek hybrid bits with the Chainsaw cutter arrangement of ION 3-D cutters, the platform allows longer intervals to be drilled along with a more robust solution for hardto- drill applications. Advanced hybrid technologies with high-density diamond-impregnated elements deliver a flexible element that’s tough yet wear-resistant, and HydroShear nozzles have been added to the platform to minimize heat cutter degradation and increase hydraulic shear near the cutter face. nov.com

System provides shale inhibitive properties at low cost

Newpark Drilling Fluids has released Navigate, a direct emulsion fluid system. In today’s performance-driven unconventional environments, operators are seeking new ways to deliver a higher quality and more productive wellbore in fewer days and at a lower cost. Navigate was derived through a rigorous product development process focusing on material optimization and has resolved problems associated with conventional invert emulsions. Where formation stability and/or losses are a concern, Navigate provides shale inhibitive properties at a lower cost than conventional invert emulsions. Its shear-thinning rheological characteristics allow a lower retention on cuttings. In a recent well the Navigate fluid system saved the operator time and money by drilling 28% faster and coming in 33% under budget in the highly unconsolidated and troublesome Oklahoma shales. newparkdf.com

Enhancing hydrocarbon recovery with nanomechanical process

Improving well intervention technologies such as hydraulic fracturing and remediation to effectively and efficiently stimulate productivity remains a challenge. Nissan Chemical America Corp. (NCA) will showcase nanoActiv HRT, a high-efficiency hydrocarbon recovery technology well intervention additive package and method. nano- Activ HRT particles penetrate beyond the induced fracture network on a nanoscopic scale, producing a diffusion- driven mechanical force known as disjoining pressure. These particles deliver long efficacy in the recovery of hydrocarbons, fragmenting them into smaller droplets and enabling an efficient backflow to the wellbore. Over the past two years this technology has been applied in more than 50 wells in the Permian Basin in several reservoirs (Wolfberry, Wolfcamp B, Wolfcamp Sand, Brushy Canyon, Woodford, San Andres) and in North Dakota (Three Forks, Bakken, Codell-Niobrara). In these applications nano- Activ HRT has significantly reduced decline rates after stimulation while consistently delivering higher oil cuts and gas/oil ratios in conventional and unconventional reservoirs. nanoActiv.com

Test mechanical properties of well cement

Test mechanical properties of well cement

The TLF-112 triaxial mechanical properties testing system from OFI Testing Equipment Inc. is the first instrument specifically designed to physically measure the complete mechanical properties profile of well cements. It provides compressive strength, Young’s modulus, Poisson’s ratio and tensile strength (Brazilian method) measurements of set cement samples. These samples can be tested at temperatures up to 240 C (400 F). Confining pressures up to 10,000 psi are applied through an integrated pressure system, which makes operation simple and easy. The compressive strength of a sample is first calculated by applying force until the sample fails. On a separate sample, the precision hydraulic system automatically applies cyclical forces (stresses), while strain gauges measure the dimensional changes. The advanced software uses stress and strain to calculate Young’s modulus and Poisson’s ratio. Indirect tensile strength is measured by applying force to the sides of the sample via a special fixture until failure. ofite.com

System relieves alert overload

System relieves alert overload

The Manage-By-Exception (MBE) system provides the alerts needed when and where users need them. Operators have numerous wells that need to be monitored at all times. Paying attention to each screen and which alerts are most important can be unmanageable. The result is alert overload. MBE lets users define what alerts they wish to see and constantly monitors the condition of the defined rule. The system then raises only the priority alert to exactly the right person, relieving alert overload and ensuring people are paying attention to only the most important alerts. Alerts are distributed to all global users, are viewable to online users and are sent via email and SMS text to remote personnel. An alert activity stream brings the mission-critical and related drilling conditions front and center, improving the user’s situational awareness. MBE generates notifications on predictive alerts and events and includes a display link providing detailed analysis. petrolink.com

The last word in last-mile logistics

The last word in last-mile logistics

PropX will be showcasing its PropX Box system and PropBeast Conveyor Belt, which can move up to 20% more proppant per truckload, and because the trailers are standard off-the-shelf flatbed trailers, each truckload costs less to transport. In addition, PropX systems emit much less silica dust than incumbent methods, allowing customers to meet the expected 2018 OSHA standards. Because unload times at the wellsite are an order five to 10 minutes per load rather than 45 to 60 minutes per load and fewer truck traffic jams occur, demurrage (standby time for truckers) is eliminated. The gravity- fed containers are quiet and very efficient, with one Denver-Julesburg fracturing crew delivering more than 9.2 million pounds of sand during a recent 24-hr period and doing it dust-free. PropX systems were designed to help protect the environment. propx.com

Plug provides efficient pump down, secures frack and quick mill up

Rubicon Oilfield International has released the Rzr- FRAC Composite Frac Plug. The patent-pending design provides 10,000 psi at 149 C (300 F) anchor and seal using 70% less material than the industry-accepted alternative. Engineers focused on creating the most optimized composite fracture plug designed to provide efficient pump-down, secure frack and quick mill-up. The plug’s plastic seal ring delivers a competent seal without responding to fluids, providing a more efficient pump-down operation with significantly less risk. During the fracture, the slips have been designed specifically to interface with the inside diameter (ID) of the casing, providing a higher anchoring force. Finally, during mill-up the 100% composite construction, 24 small ceramic buttons and large ID provide an average mill time of five minutes with very small cuttings. The Rzr- FRAC portfolio includes plugs to cover all the standard casing sizes. rubicon-oilfield.com

Company provides real-time fracture diagnostics

Seismos provides customers with stage-by-stage fracturing insights including fracture conductivity, fracture network complexity, fracture closure rates, cluster treatment analysis, proppant placement efficiency, gel breakdown times and more. With a combination of smart instrumentation, software and geophysics, Seismos provides real-time fracture diagnostics. The company shows operators their ability to optimize designs and prevent over-flushing to obtain optimal per-stage conductivity. The real-time application allows users to modify designs on the fly to optimize every stage’s production. This requires no operational impact, no offset wells and zero geologic restrictions. seismos.com

Liquid-in/liquid-out problems of downhole chemical tracing solidly solved

Liquid-in/liquid-out problems of downhole chemical tracing solidly solved

Any liquid pumped into a formation with pressure is just as easily squeezed out of the formation via pressure. This liquid-in/liquid-out phenomena has been a known problem in the downhole chemical tracing industry for years and produces inflated and/ or false positive readings of tracer recovery. Newly patented SOLID tracer chemical products successfully address the pressure-related limitations of liquid tracer chemicals. The solid particulates (sized 40/70 sand) are pumped into the fracture pack during stimulation and transported deep into the formation along with the proppant. The solid particulates remain locked in the fracture pack, thereby eliminating the liquid-in/liquid-out data errors. These new particulate tracers provide accurate short-, medium- and long-term datasets. spectrumtracer.com

Stay ahead of the competition

The Sproule Type Curve Analysis Database and Report helps operators shorten time spent screening opportunities, evaluating producing wells and benchmarking performance. From evaluating acquisition and divesture opportunities to development planning, everyday critical business decisions are made using type curves analysis. Sproule’s new up-to-date and accurate dataset helps users increase efficiency. This complete and consistent production profile dataset is available for 14 key resource plays across Western Canada. Visit Sproule at booth 2852 to receive a sample report. sproule.com

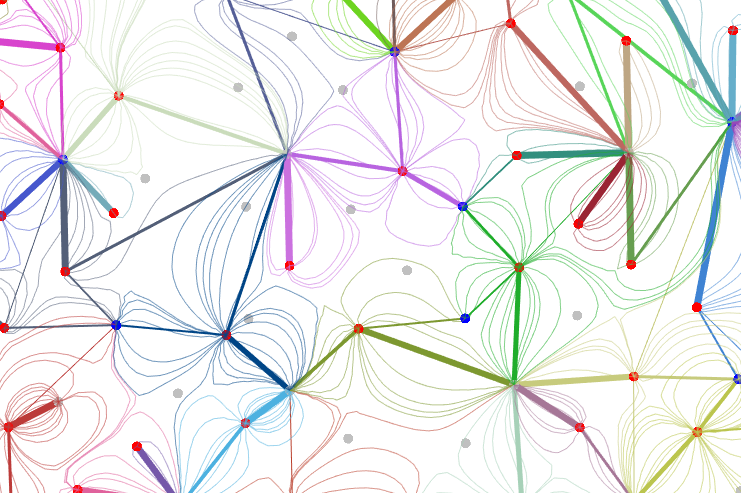

Reservoir pattern surveillance and intelligent well rate targets for mature floods

StudioSL’s reservoir pattern surveillance module is Streamsim’s solution to allow the proactive optimization of mature floods through updating well rate targets. Specifically, streamlines are used to identify well patterns, which are displayed and quantified using a patented Flux-Pattern Map (Figure 1). Based on the pattern metrics, pattern sweep efficiencies are modified through the reallocation of injected and produced volumes. As new production/injection data are collected, the analysis is repeated, allowing a nearly continuous rate-target management strategy to maximize field recovery with existing wells. StudioSL’s surveillance module promotes good sweep and demotes fluid cycling. The Flux Pattern map display is particularly helpful in justifying well rates changes to the operations team when cutting back low-efficiency oil production is needed to realign a flood. streamsim.com/technology/studiosl

FIGURE 1. Streamlined paths at a particular moment in time for a mature-pattern waterflood (top) and the associated Flux Pattern Map (bottom) with connection thickness related to each well’s production allocation factor are displayed in studioSL. Red points are producers, blue points are injectors and gray points are closed wells. A pattern is considered a parent injector with connected producers. (Source: Streamsim)

New casing technologies showcased at SPE ATCE

New casing technologies showcased at SPE ATCE

The Deadbolt SafeLok system guarantees casing integrity when using inflatable casing annulus packers to improve cement integrity against gas migration or lost circulation zones. The Deadbolt valve offers the proven reliability of the Safelok valve system with absolute assurance of preventing any casing leaks after functioning. This system allows operators to use inflatable casing annulus packers to improve casing cement integrity without any risk of creating a critical leak point in the casing. Another new technology is a hydraulic port collar that is placed above the inflatable casing annulus packer to allow cement to be placed in the annular space. The hydraulic port collar has a new closing plug seat design that, once pressure is applied, will pump out and fall to the shoe track. tamintl.com

EURs: new production forecast database of all active wells

The TGS Production Forecast Database is a library of every well in the U.S. containing both a monthly production projection and EUR total. When combined with the Longbow desktop visualization tool, entire EUR basin studies can be built in minutes. This forecast engine leverages the TGS Well Performance Database to create forward production curves for all active producing wells derived from historical production data. Curves are generated using hyperbolic fitting, but this model’s advantage includes extended Kalman filter (EKF) techniques incorporated into the process. EKF emphasizes the most recent data, identifies trends and adjusts logic on the fly using a series of matrix math techniques, resulting in improved efficiency and accuracy. It is the first time to the company’s knowledge that the EKF theory is used in oil and gas forecasting. tgs.com

This image shows a Delaware Basin side-by-side assessment of EUR values and gas-oil ratio (GOR) calculations. The left map, EUR hot spots, identifies spatial patterns of high-value wells and acreage. The right map, correlating wells by GOR value, interprets the oil and gas window in the play, enabling asset evaluators to identify commodity streams of choice. (Source: TGS)

System sets size record for expandable liner hanger installation

System sets size record for expandable liner hanger installation

The XPak expandable liner hanger/ packer system from TIW was recently used to successfully hang an 185⁄8-in. outside diameter (OD) liner in 24-in. OD electric-resistance weld (ERW) seamed casing. The system design eliminated a twostage cement job in unstable formations and provided greater well control. The liner penetrated 670 m (2,200 ft) of difficult and unstable geology, including water zones, sloughing shale and lost-circulation zones. The slip design provides a hanging load capacity equal to or greater than conventional liner hangers. Stacked metal-to-metal seals and elastomer backup seals with no extrusion gaps provide a HP/HT gas-tight liner-top seal. A honed inside diameter receptacle in the upper portion of the expander allows tieback to surface or patching a cased-hole section. Successful qualification testing prior to running the XPak system has confirmed that the modified system can effectively seal in ERW seamed casing. tiwoiltools.com

Wireless gauges provide real-time information

DATALIFT is a plunger module that lifts data from gauges downhole. Gauges record pressure/temprature data to memory and transfer data wirelessly to the DATALIFT as the module approaches the gauges. DATALIFT returns to the surface, and the acquired data are used to identify artificial lift requirements and provide production and reservoir optimization information. SHALECOMM is a real-time wireless gauge for onshore and offshore applications. The gauge generates acoustic energy to transfer data to the surface using the downhole pipe as a conduit. SHALECOMM replaces cable-based gauges, eliminating rig floor installers, downhole cables, clamps and protectors. Wireless gauges can optimize production, artificial lift and gravel/fracture pack operations. In addition, the company’s FRACWATCH high-shock wireless short-hop gauges can be placed in the horizontal section of the well and monitor the fracture flowback and are deployed as part of the casing. tubelenergy.com

Connection designed for challenging environments

Connection designed for challenging environments

Vallourec will be presenting VAM X-Force, a connection designed to mitigate drilling risks and reduce total drilling costs in challenging environments. This connection pushes the limits of the existing technologies to reach deeper, more remote hydrocarbon reservoirs while achieving higher ROP and lowering nonproductive times.

By combining the traditional doubleshoulder design with a thread profile, VAM X-Force demonstrates excellent mechanical, operational and economic performance. The tool provides high torque and fatigue life without degrading the tensile strength of the connection. It also increases the speed of makeup, saving time on the rig without degrading break-out torque. vamxforce.com

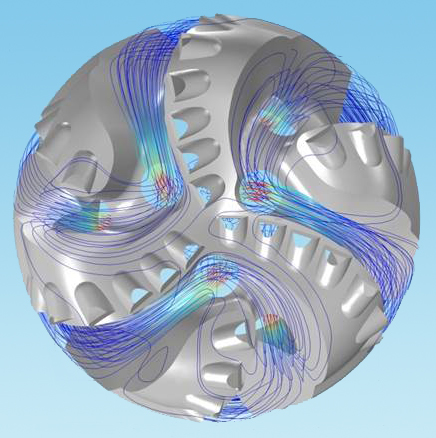

Improving cooling, cleaning and cuttings evacuation

Varel Oil & Gas Drill Bits will showcase its HYDRA hydraulics optimization program for tailoring PDC bit hydraulics. The program improves bit performance with better bit cooling and cleaning along with more effective cuttings removal. The Hydra approach precisely applies curved nozzles, webbed blades and other features using computational fluid dynamics to match the design to the application. The curved nozzles reduce coreouts, plugged nozzles and bit balling, while webbed blades limit cuttings recirculation, eliminate entrainment and increase cuttings volume. Fine-tuning these technologies for the application using the HYDRA optimization program is significantly improving cooling, cleaning and cuttings evacuation for greater bit life and drilling efficiency. Vertical and lateral applications in the Permian Basin have improved ROP and footage drilled in softer clays and shale as well as sands and limestone. For instance, in a Wolfcamp Formation lateral the optimized bit increased ROP 58% and footage by 98%. varelintl.com

Technology enables surface water discharge

Veolia Water Technologies will be showcasing its CoStrip degasifier technology in a technical paper to be presented Wednesday, Oct. 11, at 3:45 p.m. in the Process and Monitoring session. CoStrip effectively removes dissolved gases without the need for pretreatment. Unlike conventional degasification towers with packed beds susceptible to plugging and fouling, Veolia’s patent-pending CoStrip degases raw water by introducing microbubbles of a stripping gas counter-current to the liquid stream. Typically installed in a treatment train that enables surface water discharge, it reduces chemical and sludge costs when paired with chemical softening and extends the life of reverse-osmosis membranes. CoStrip is designed for easy reliable maintenance-free operation and can be supplied as a fully assembled skid-mounted system for easy installation and lower total installed costs. For more information, visit the company at booth 1233 to learn more. veoliawatertechnologies.com/en

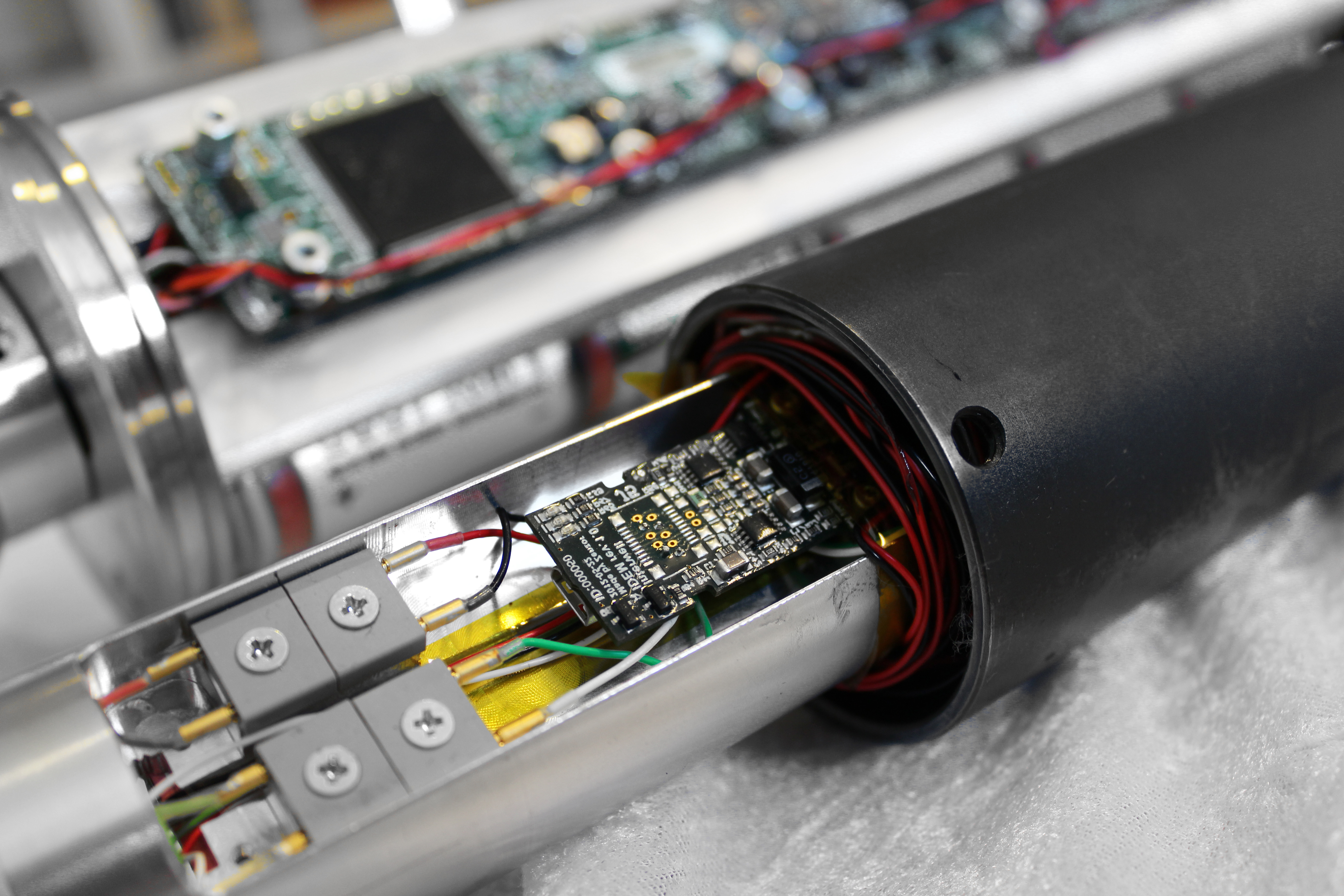

Tools provide a more complete understanding of downhole issues

Tools provide a more complete understanding of downhole issues

Visuray will be showcasing its downhole X-Ray Platform, a family of tools and services. There will be specific focus on the new VR90s advanced diagnostic service, which is commercially available. The VR90s tool features a smaller tool diameter and higher temperature rating compared to the original VR90 downhole X-ray diagnostic tool, along with millimetric scanning of zones of interest and a wider field of view. During intervention activities Visuray’s downhole X-ray diagnostic services provide reliable imaging in any well production fluid without special well preparation. With its improved specifications, the new VR90s tool brings the power of X-ray diagnostics to more wells and provides a more complete understanding of the downhole issue, thus allowing operators to work more efficiently. visuray.com

Mitigate risk and optimize performance

Mitigate risk and optimize performance

Weatherford will feature technologies for drilling performance, fracturing and completion optimization, production optimization, and digital intelligence. These tools include not only new technologies but also proven solutions. The ForeSite production optimization platform connects the entire production ecosystem to maximize performance throughout the reservoir, wells and surface facilities. The AccuView system supports a real-time collaborative environment and facilitates significant strides in well-construction efficiency. The conventional AutoTong system automates the makeup, breakout and evaluation of pipe connections to enhance well integrity. The company’s Compact wireline tools have a long history of reliable performance, helping customers acquire reservoir data efficiently and safely. In addition, smart gas-lift systems monitor production and control injection, and jet-lift systems deliver high volumes without failure, increasing uptime. By connecting insights from the wellsite to the office and combining historical data with forward-looking technologies, Weatherford helps customers mitigate risk and optimize performance. weatherford.com

Recommended Reading

Exxon Slips After Flagging Weak 4Q Earnings on Refining Squeeze

2025-01-08 - Exxon Mobil shares fell nearly 2% in early trading on Jan. 8 after the top U.S. oil producer warned of a decline in refining profits in the fourth quarter and weak returns across its operations.

Phillips 66’s NGL Focus, Midstream Acquisitions Pay Off in 2024

2025-02-04 - Phillips 66 reported record volumes for 2024 as it advances a wellhead-to-market strategy within its midstream business.

Rising Phoenix Capital Launches $20MM Mineral Fund

2025-02-05 - Rising Phoenix Capital said the La Plata Peak Income Fund focuses on acquiring producing royalty interests that provide consistent cash flow without drilling risk.

Equinor Commences First Tranche of $5B Share Buyback

2025-02-07 - Equinor began the first tranche of a share repurchase of up to $5 billion.

Q&A: Petrie Partners Co-Founder Offers the Private Equity Perspective

2025-02-19 - Applying veteran wisdom to the oil and gas finance landscape, trends for 2025 begin to emerge.

Comments

Add new comment

This conversation is moderated according to Hart Energy community rules. Please read the rules before joining the discussion. If you’re experiencing any technical problems, please contact our customer care team.