Inventory undersupply. Inventory oversupply. Delivery delays. Miscommunications.

Customers struggling with those issues were looking for efficiencies in managing oil country tubular goods (OCTG) from planning through drilling. International pipe supplier Tenaris devised a solution that would place the entire process under one umbrella, creating efficiencies in time and inventory, reducing personnel, cutting road traffic and, perhaps most importantly, making the rig site safer, said Chief Commercial Officer Guillermo Moreno.

“We understood that, in order to serve our clients properly, we needed to understand their operations, their needs at the time, what their future needs would be in terms of products and services, and see in which way we could integrate the operations in order to make them simpler, faster and, particularly, more efficient,” he said.

The path to Rig Direct

Tenaris is not new to the U.S. The company began its U.S. operations in the 1980s and brought in its direct delivery options around 2015. It had begun working closely with end-users in the 1990s, Moreno said, mostly in Mexico and Argentina where the company had a strong industrial presence in manufacturing.

Its U.S. footprint increased significantly with the acquisitions of OCTG and premium connections manufacturers Maverick Tube Corp. in 2006 and Hydril in 2007. But the main driver for introducing its new supply chain solution in the U.S. was its investment in a greenfield seamless mill in Bay City, Texas, which started operations in 2017. In 2020, Tenaris also acquired IPSCO.

Before developing its Rig Direct system, Moreno said, there were sometimes issues involving inventory oversupply/undersupply, delivery delays when pipe orders had to be changed and other miscommunications that could lead to excess pipe being scrapped—at great cost.

“Our clients were asking us for more. They needed to improve their operations. They needed to reduce their costs,” he said. “Because of the shales, they were confronting a new reality, due to the different plays but also because of the different technologies. New products were needed and changes in design happened faster than before, so it was clear that it was the time, and now we were prepared, because we had a strong industrial footprint, to be able to bring the Rig Direct model to the U.S. and Canada.”

How it works

The process starts with Tenaris joining the client in well planning and supply chain forecasting. The exact amount of involvement depends on the specific needs of the customer, Moreno said.

“With visibility into drilling projects, we define the best material for the well and we can evaluate and anticipate potential challenges downhole,” he said. “This brings more accuracy and avoids what in the past was miscommunication—what I need, where I need it, the quantity—so now everything is traceable; communication is clear and more efficient.”

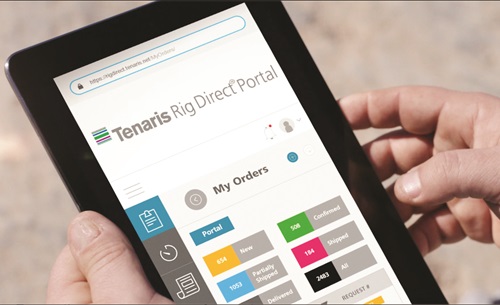

With Rig Direct, all data about the pipe, order, delivery and other aspects are integrated into a single platform. “We have streamlined and simplified administrative workflows digitally,” Moreno noted.

Site management

There are no third-party distributors. Instead, Tenaris manages its own yards and service centers, delivering the pipe directly to the rig site. Site delivery, geared it to the client’s requested schedule, is planned through the Rig Direct portal.

In addition to manufacturing and delivery efficiencies, this system results in fewer people handling the pipe at the site, Moreno said. There is no longer a need for a clean, visual and drift crew. “We developed RunReady, a service that delivers pipes to the well ready to be run. With this unique offering, our technicians manage material preparation, performing visual inspections of the pipe and applying a dual-purpose compound at the mill.”

At the rig site, the Tenaris team oversees delivery and offloading with digital tallies, which was another system initiated by client request. A major operator told the Tenaris team that there were too many people on the rig, leading to safety issues. The client asked, “If you could send us pipe that is ready to be run, this will not only reduce our cost but it will also make our operations safer.”

There is also remote monitoring, developing a torque turn service to guide the make-up of each pipe that allows Tenaris to bring more accuracy to the operation, remotely get feedback on the process and use that data for making further improvements.

Improving along the way

The first phase of Rig Direct involved the logistics management of getting pipe from mill to yard to well, synchronizing production with the end user’s drilling programs. The second phase included additional development of services for customers such as digital integration (Pipe Tracer, RunReady, Rig Direct Portal).

The newest version, phase three, involves the development of remote monitoring tools.

“We’re going to have a direct communication with the rig where we’re going to see torque turn monitoring system, and leverage the iRun Casing tool for real-time casing installation,” Moreno said. “That will mean even fewer people on the rig.”

Another safety improvement is Tenaris’ own people handling the pipe from the mill to delivery at the rig.

“This is how to make sure you have the right people, they’re properly trained,” he said. “There’s so much information, so much knowledge, so many people coming onsite, it is so difficult for operators to maintain that level of consistency. But when we send these operations to a central area, they use their expertise to monitor, wherever the location is. This is where we are headed today.”

“We have put together all the services so the end user only needs to deal with one company,” Moreno said. “And if there is a question, they know they can come to us.”

Further refinements

As part of its commitment to ongoing system maximization, Tenaris in early November announced a multifaceted addition to the Rig Direct package. Called WISer, the new suite is designed to enhance well integrity, safety, efficiency and reliability in the well construction process.

WISer includes two digital features:

iRun Casing cloud-based tool. This enables real-time monitoring of casing installation to minimize the risk of lost lateral length and production. It also aims to prevent accessibility issues caused by fatigue damage, buckling, overtorque or stuck pipes.

Torque turn monitoring system. With this system, Tenaris field service experts collect and analyze real-time torque data at the well using advanced equipment. The plan is to improve connection make-up reliability, reduce errors and enhance the overall integrity of the assembly.

Recommended Reading

Aris CEO Brock Foresees Consolidation as Need for Water Management Grows

2025-02-14 - As E&Ps get more efficient and operators drill longer laterals, the sheer amount of produced water continues to grow. Aris Water Solutions CEO Amanda Brock says consolidation is likely to handle the needed infrastructure expansions.

Halliburton, Sekal Partner on World’s First Automated On-Bottom Drilling System

2025-02-26 - Halliburton Co. and Sekal AS delivered the well for Equinor on the Norwegian Continental Shelf.

E&P Highlights: March 3, 2025

2025-03-03 - Here’s a roundup of the latest E&P headlines, from planned Kolibri wells in Oklahoma to a discovery in the Barents Sea.

How DeepSeek Made Jevons Trend Again

2025-03-25 - As tech and energy investors began scrambling to revise stock valuations after the news broke, Microsoft Corp.’s CEO called it before markets open: “Jevons paradox strikes again!”

Pair of Large Quakes Rattle Texas Oil Patch, Putting Spotlight on Water Disposal

2025-02-19 - Two large earthquakes that hit the Permian Basin, the top U.S. oilfield, this week have rattled the Texas oil industry and put a fresh spotlight on the water disposal practices that can lead to increases in seismic activity, industry consultants said on Feb. 18.

Comments

Add new comment

This conversation is moderated according to Hart Energy community rules. Please read the rules before joining the discussion. If you’re experiencing any technical problems, please contact our customer care team.