High temperature, a phenomenon of the industry’s drive into new and complex frontiers, continues to push the limits of technology, as evidenced by ongoing development of tools that can deliver performance and reliability in extreme environments. Rotary steerable systems (RSS) are commonly deployed in wells that present challenging trajectories and temperatures as high as 175 C (350 F), enabling operators to drill and produce wells that were once inaccessible.

However, the continued push into increasingly harsher environments, where downhole temperatures can reach or exceed 200 C (392 F), has established a new threshold for ultrahigh-temperature (UHT) performance.

When it comes to the reliability and longevity of downhole electronics exposed to UHTs, distortion of plastic components is among the industry’s biggest challenges. This limitation, which often results in failure or drilling blind, has raised the bar yet again for a new wave of innovation and technology development when it comes to RSS. As operators strive to meet drilling objectives and manage costs, drilling systems that can improve performance in these downhole conditions is now essential.

A newly designed system with UHT-rated electronics has expanded the operating envelope in extreme downhole conditions, enabling drillers to accurately and efficiently reach total depth (TD) using standard drilling procedures. Petróleos Mexicanos (PEMEX) successfully used the 200 C-rated system on a high-temperature exploratory well with a complex trajectory in the Sureste Basin, one of Mexico’s most prolific and long-producing offshore oil fields.

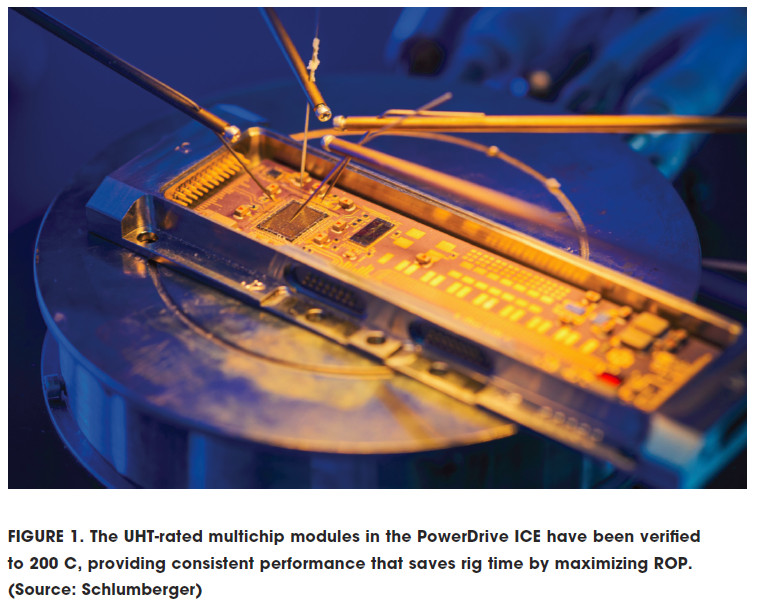

Introduced in March 2015, the PowerDrive ICE ultraHT system was developed by Schlumberger specifically to overcome the effect of UHT on the electronics of downhole RSS components (Figure 1). Historically, the industry has met this challenge by flasking the electronics or mitigating failures by staging to reduce the thermal shock of the electronics, which slows down the operation. A lot of time is spent circulating to ensure that non-UHT-rated tools properly cool down.

The new system has been designed and built to drill UHT wells using standard operating procedures. This greatly reduces time spent circulating to cool the bottomhole assembly (BHA) and eliminating the need for costly mud coolers at the surface.

As the latest addition to the PowerDrive RSS portfolio, the new ultraHT system offers a drilling solution that features integrated ceramic electronics (ICE) and multichip modules with metal-to-metal sealing components that replace elastomeric seals to withstand rugged downhole conditions, including UHT.

The fully rotating system delivers precise directional control and automatic steering to increase ROP and reduce risk. This capability gives operators greater assurance that the system will not experience failure, which can result in pulling out of the hole and thus adding time and cost to the operation.

Prior to field testing in 2014, the ultraHT system underwent extensive verification and validation, with thousands of hours of rapid testing above 200 C and as low as -40 C (-40 F) for thousands of cycles and under shock to ensure the electronics in the system would function normally in extreme operating environments.

Complex well trajectory in UHT reservoir

In conjunction with a new exploratory campaign in the Sureste Basin, PEMEX faced a host of challenges in drilling an 1,100-m (3,609-ft) 8½-in. hole section in a deep formation with extreme conditions. The plan called for drilling a J-shaped well profile with precise inclination control to achieve a 25-degree inclination. The deviated configuration was unusual for an exploration well, which is typically vertical.

Further complicating the project, BHA temperatures in the reservoir were anticipated to exceed 190 C (374 F), as evidenced by the 170 C (338 F) temperature measured just above the 8½-in. section, dangerously close to the 175 C rating of most high-temperature-rated RSS technologies. The hard formation also necessitated using a heavy mud weight of up to 17 ppg, which likely would result in high solids content.

The project represented a collaborative effort between PEMEX and Schlumberger, with extensive upfront planning and decision-making to find a solution that would overcome the limitations of conventional drilling tools. A downhole mud motor was tried in the 8½-in. section with no success in providing directional control because of the difficulties in sliding at the 6,067-m (19,904-ft.) depth. The use of a turbine was not viable because it would likely present problems with rig pressure capabilities.

After determining that RSS technology provided the only reliable method for achieving the dogleg severity to reach the planned trajectory, PEMEX opted to integrate the UHT system into the BHA, rated to withstand the UHTs up to 200 C and also precisely steer the difficult trajectory in the hard formation and heavy mud weight conditions.

Using an integrated drillbit design platform, Schlumberger modeled the interaction of the bit and the rock and determined that a high-abrasion-resistant polycrystalline diamond compact bit would provide the greatest ROP for the hard rock conditions when combined with this BHA, which also included MWD tools for transmitting real-time resistivity, gamma ray, inclination and annular pressure-while-drilling data for optimized reservoir evaluation.

Reaching geological target

With the ultraHT system deployed for 333 m (1,093 ft), PEMEX was able to build the inclination of the well from 17.5 degrees to 26.3 degrees to both obtain a geological target and then maintain the tangent in automatic hold mode to reach the planned trajectory at an estimated static temperature of 181 C (358 F) at the end of the last run.

The BHA achieved a dogleg severity of up to 2.94 degrees per 30 m (100 ft). The metal-to-metal seals in the system withstood the UHT as well as the heavy mud weight and high solids content. Throughout the 13-day operation, the system performed reliably in BHA temperatures that reached 181 C. PEMEX plans to deploy the system for several upcoming exploratory wells targeting the same reservoir, where more UHT wells are expected.

The ultraHT system, which can be used on land as well as offshore, has had several runs in Mexico as well as the Gulf of Mexico and Vietnam. It also has potential applicability for the growing high-temperature markets in North America and the Middle East.

The new system is designed to work in concert with the TeleScope ICE ultraHT MWD service, which transmits survey and formation evaluation data at high speed to optimize real-time well placement and reduce risk in harsh drilling environments. The new UHT MWD service was designed and built with exactly the same objective as PowerDrive ICE—to operate reliably in the UHT environment as a standard operating procedure. Together, the two systems make up the industry’s first complete BHA designed to operate at 200 C.

Precision, reliability and durability are critical for meeting drilling objectives and managing costs in UHT wells, where conventional RSS cannot efficiently or cost-effectively meet operators’ objectives. By providing a solution that can address the multiple challenges of this growing market, the ultraHT system is expanding the operational envelope, enabling drillers to overcome significant hurdles to drill otherwise undrillable wells.

Recommended Reading

Liberty Bolsters Mobile Power Business with Acquisition of IMG Energy

2025-03-05 - Liberty Energy Inc. said March 5 it had purchased IMG Energy Solutions as the company expands its mobile power business.

Sitio Fights for its Place Atop the M&R Sector

2025-04-02 - The minerals and royalties space is primed for massive growth and consolidation with Sitio aiming for the front of the pack.

Tamboran, Falcon JV Plan Beetaloo Development Area of Up to 4.5MM Acres

2025-01-24 - A joint venture in the Beetalo Basin between Tamboran Resources Corp. and Falcon Oil & Gas could expand a strategic development spanning 4.52 million acres, Falcon said.

Devon, BPX to End Legacy Eagle Ford JV After 15 Years

2025-02-18 - The move to dissolve the Devon-BPX joint venture ends a 15-year drilling partnership originally structured by Petrohawk and GeoSouthern, early trailblazers in the Eagle Ford Shale.

Huddleston: Haynesville E&P Aethon Ready for LNG, AI and Even an IPO

2025-01-22 - Gordon Huddleston, president and partner of Aethon Energy, talks about well costs in the western Haynesville, prepping for LNG and AI power demand and the company’s readiness for an IPO— if the conditions are right.

Comments

Add new comment

This conversation is moderated according to Hart Energy community rules. Please read the rules before joining the discussion. If you’re experiencing any technical problems, please contact our customer care team.