The seismic industry is expanding its reach from exploration activities to the operational world of drilling, completions and production. Offering detailed geologic information in a practical and useful way through innovative seismic acquisition and quick delivery of active and ambient seismic attributes provides detailed and actionable information for well planning and completion design.

This shift addresses two significant needs of the industry. The first is the long-standing and ever-increasing need for innovation in the land seismic business that reduces environmental impact, cuts costs and increases efficiency without compromising data quality. The second is a growing need for a quick solution that provides the insight needed for accurate geosteering or fault avoidance on well tracks.

E&P operators have responded to some of these needs with advancements of their own. One is pad drilling, which allows for significant subsurface development by concentrating wellheads at the surface, thus increasing efficiency and decreasing environmental impact.

Practical information

Global Geophysical has developed a suite of services and a new product offering that meet both of the aforementioned needs while complementing advancements that operators have already achieved. By naturally leveraging its 3-D seismic, ambient seismic, microseismic monitoring and processing technology, the company is able to deliver full and actionable information to engineers at a scale and pace that are practical for the operational world of drilling, completions and production.

A key aspect of this capability is a new, patented 3-D design method that, when coupled with the efficiency of the AutoSeis autonomous nodal recording system, makes acquisition fast and affordable, meaning days rather than months in the field.

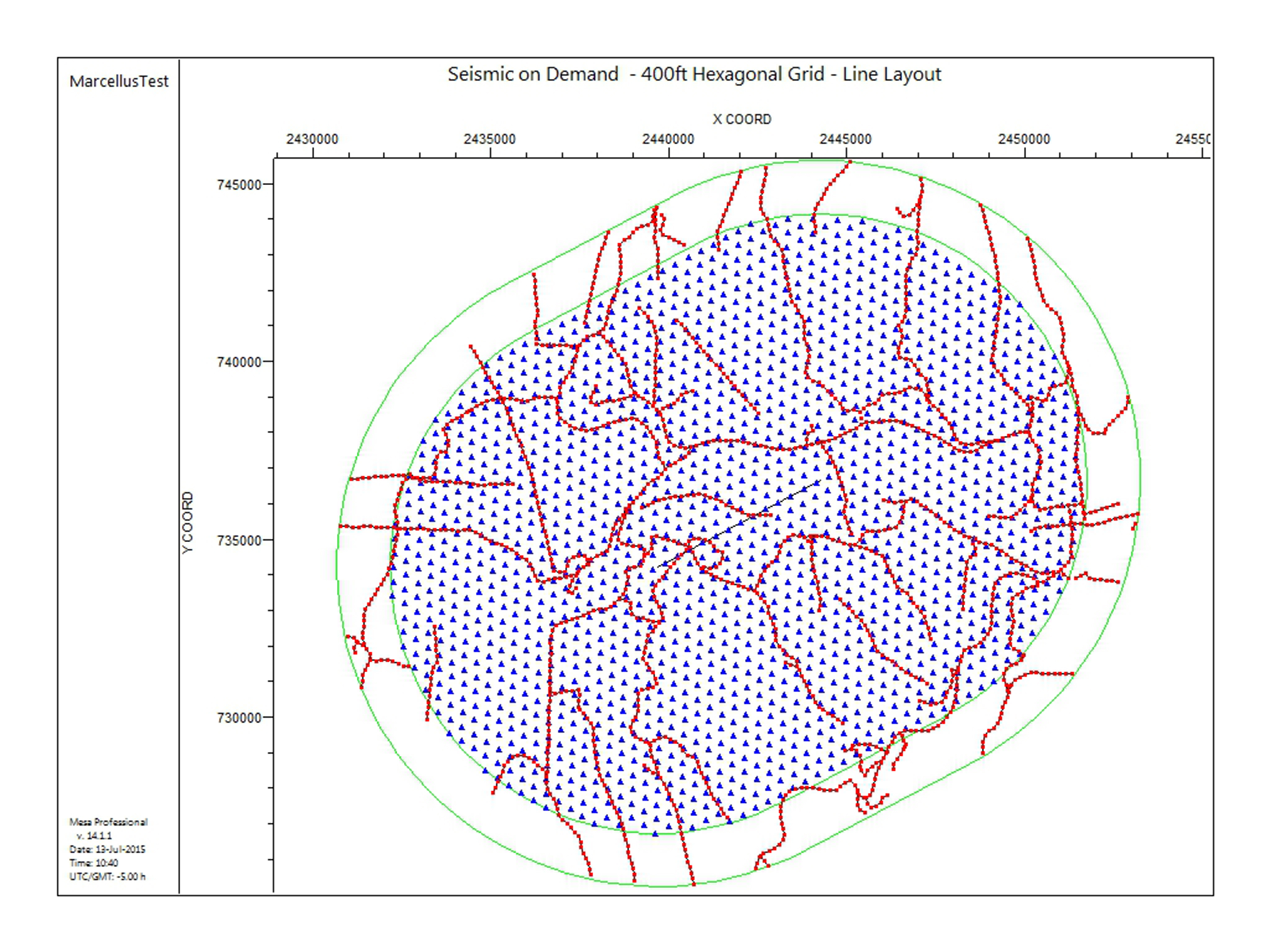

The capability takes advantage of a paradigm shift in 3-D acquisition design that works to optimize receiver location and coverage fold rather than just maintain the most symmetrical grid design possible. Using this new method, the company is moving away from the old model of 3-D design that starts with and aims to preserve a symmetrical grid of source and receiver points. This innovation enables those points to be moved around to accommodate surface and cultural obstacles by starting with accessible source positions on preexisting roads and trails and designing the optimal receiver positions around them to maximize subsurface coverage.

Running vibrators on existing roads, trails and fallow fields can significantly reduce costs by eliminating environmental damage associated with line cutting, drilling and the use of explosives. This also reduces the need for environmental permits, which is an important factor in gaining surface permission and reducing the timeline for operating in many foreign countries and on government-regulated lands in the western U.S. Global’s new method represents an advancement in the way the company

designs these random 3-D surveys to achieve more consistent subsurface coverage.

Brazil program

This paradigm shift came out of a first-of-its-kind acquisition program in Brazil.

In October 2014 the company completed Brazil’s first 3-D vibroseis acquisition program. Due in part to environmental concerns, vibroseis technology has been utilized sporadically in Brazil and took an almost 25-year hiatus before Global began importing vibrators into the country in 2010. The company has made a name for itself in the Brazilian onshore seismic market through its use of vibes on roads, which significantly reduces the environmental impact of land seismic data acquisition. Using this method, the company has recorded more than 30,000 linear km (18,640 linear miles) of 2-D data in less than four years, providing much-needed seismic data in the underexplored Parnaiba and San Francisco basins. The success of the company’s 2-D vibroseis projects has created increased interest in the technology for the acquisition of 3-D vibroseis data as well.

The 3-D vibroseis program highlighted the flexibility of the AutoSeis autonomous nodal recording technology and the company’s advanced 3-D vibroseis techniques for limited-access situations. The goal of the program was to capture high-quality 3-D seismic data with source locations bound to preexisting roads in a “pseudo-random” configuration.

The design included 41 receiver lines at two different azimuths of 45 degrees and 135 degrees, a configuration that Global

refers to as a “double orthogonal” grid. Despite limited access, this layout ensured that all bins had adequate fold within the offsets of interest. The sources were positioned on roads in approximately 50 separate segments in a pseudo-random pattern. More than 2,170 source points were spread over an area of 29.7 sq km (11.5 sq miles), resulting in an adequate source density of 73.3 source points per 1 sq km (0.4 sq miles).

While significant time was expended in planning, scouting and surveying the project, recording took just five days, and the results exceeded client expectations. The final migrated data volume provided a clear indication of the areal extent of the structural high at the client’s target horizon. The atypical 3-D design and the flexibility of the AutoSeis system led to the ultimate success of the project both geophysically and commercially.

The success of the Brazil program spurred the expansion of the acquisition methodology to other applications. Specifically, the company used its access-constrained method to design an acquisition scenario with respect to a single horizontal well in the Utica Shale. Global once again developed a random 3-D layout with vibrators constrained to existing roads. More than 1,690 source points were spaced over 31 sq km (12 sq miles) of road in the area of interest. It was determined that a receiver line azimuth of 122 degrees would provide the highest fold data. Parallel receiver lines were laid out at a distance of 251 m (825 ft) at the optimal azimuth. The final irregular design provided more than 125 fold at the Utica target, which was higher than that provided by previous conventional 3-D designs using dynamite in the area.

The Utica example confirmed that the paradigm used on the Brazil 3-D vibroseis program is a viable acquisition method, with applications for a variety of restricted areas. In both Brazil and the Utica, the company employed this patented acquisition design methodology, demonstrating its capacity for affordable acquisition of wide-azimuth high-resolution long-offset

3-D seismic data in otherwise inaccessible areas. The model improves upon previous techniques for designing 3-D surveys in areas where vibroseis source positions are confined to roads and trails. Both of these exercises determined that fold of coverage can be optimized by orienting the receiver grid to minimize the number of receiver lines parallel to the source lines. This patented methodology is a better procedure than starting with a nominal grid of sources and receivers and subsequently moving the sources to accessible locations. In this new 3-D design model, average fold variation is an attribute that can help choose optimal receiver line orientation. Additional 3-D designs from Brazil, Colombia and Ohio, where source

locations are constrained to vibe-accessible areas, have demonstrated that even with relatively sparse road networks, good fold at the target horizon is achievable with this method.

Furthermore, this paradigm reduces environmental impact by eliminating the need for dynamite sources, line clearing or driving vibes off of roads. Working on preexisting roads also greatly increases the efficiency of the crew, and eliminating shot hole drilling costs can be a significant cost savings, both of which are necessities in the current oil price environment.

Improved efficiency, reduced environmental impact and cost savings make seismic an affordable and applicable technology to the world of operations in addition to its more traditional use in exploration activities. This paradigm shift has clear applications to the pad-based drilling of today and significant potential for surveys dedicated to wellbores in unconventional plays.

Recommended Reading

Artificial Lift Firm Flowco Seeks ~$2B Valuation with IPO

2025-01-07 - U.S. artificial lift services provider Flowco Holdings is planning an IPO that could value the company at about $2 billion, according to regulatory filings.

Diamondback Energy Appoints Industry Veteran Holderness to Board

2025-02-04 - Diamondback Energy has named Darin G. Holderness, who founded and served as CFO at P&A Exchange LLC and CFO at ProPetro Holding Corp. as a board of directors at the Permian Basin E&P.

Artificial Lift Firm Flowco’s Stock Surges 23% in First-Day Trading

2025-01-22 - Shares for artificial lift specialist Flowco Holdings spiked 23% in their first day of trading. Flowco CEO Joe Bob Edwards told Hart Energy that the durability of artificial lift and production optimization stands out in the OFS space.

Utica’s Infinity Natural Resources Seeks $1.2B Valuation with IPO

2025-01-21 - Appalachian Basin oil and gas producer Infinity Natural Resources plans to sell 13.25 million shares at a public purchase price between $18 and $21 per share—the latest in a flurry of energy-focused IPOs.

Not Sweating DeepSeek: Exxon, Chevron Plow Ahead on Data Center Power

2025-02-02 - The launch of the energy-efficient DeepSeek chatbot roiled tech and power markets in late January. But supermajors Exxon Mobil and Chevron continue to field intense demand for data-center power supply, driven by AI technology customers.

Comments

Add new comment

This conversation is moderated according to Hart Energy community rules. Please read the rules before joining the discussion. If you’re experiencing any technical problems, please contact our customer care team.