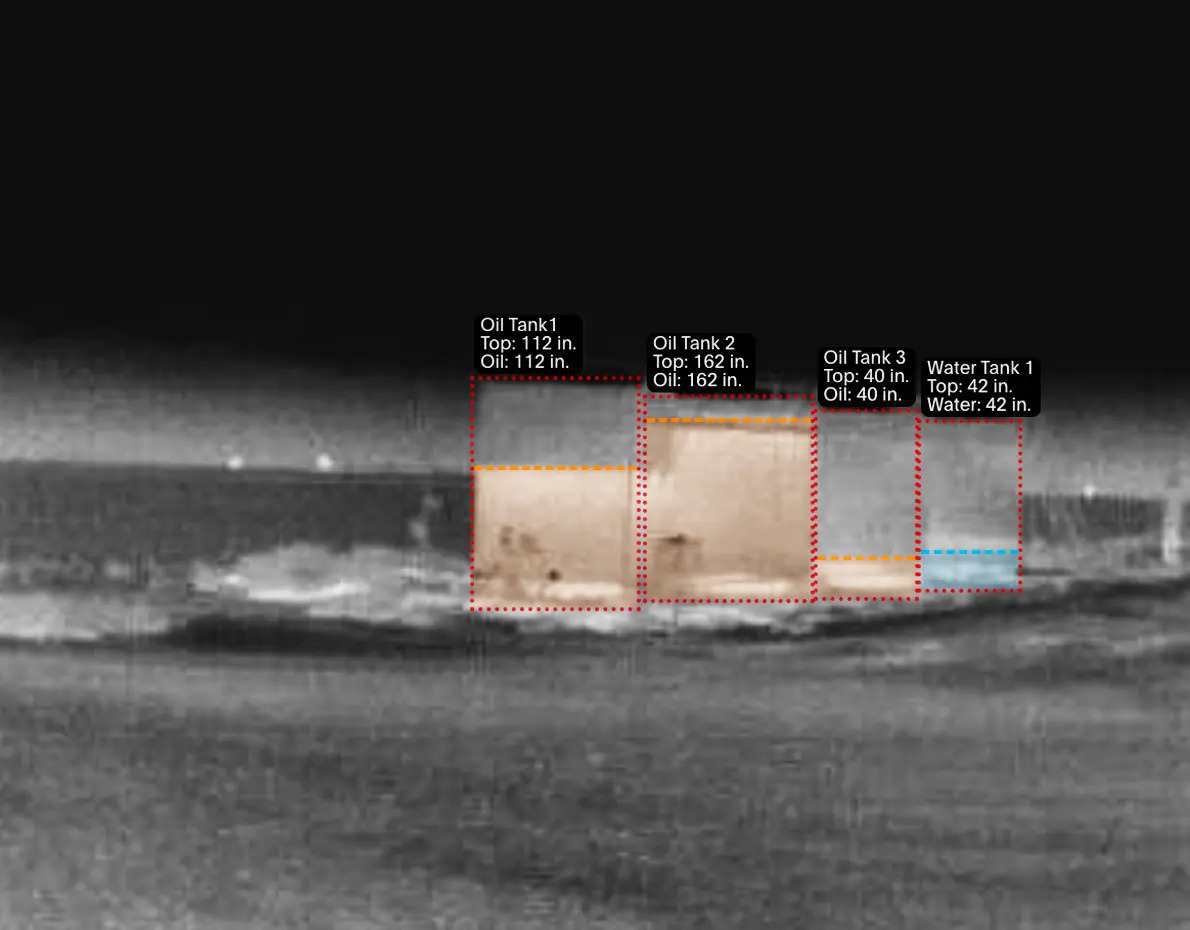

Andium’s camera in the field (Source: Andium)

Oilfield operations have long used outdated, manual methods for measuring tank levels, such as using a gauge and jotting down readings on carbon paper, much like checking oil in a car.

Tech company Andium set out to fix the industry’s glaring problem.

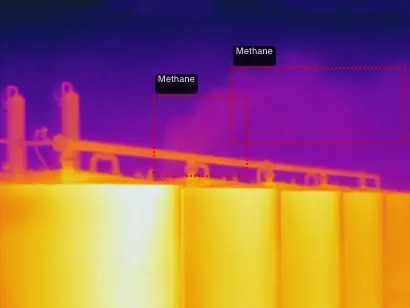

Founded by Jory Schwach, Andium began developing a system using thermal cameras to monitor oil and gas tank levels in 2014. Now, thanks to advances in imaging and AI, Andium can also help track methane and CO2 emissions with a package of cameras, sensors and software.

And the industry has taken notice.

Andium has 25 paying customers including major players like Solaris, ConocoPhillips, Chord Energy and Origin in Australia. It recently closed a $21.7 million Series B funding round led by Aramco Ventures, which brought the company’s total funding to over $40 million.

The initial idea for Andium came from Schwach’s graduate studies, where he worked on a project using cameras to control traffic light intersections. Schwach envisioned using thermal cameras to create a similar technology for the oil and gas industry.

“The second derivative of heat, which measures the rate of change of heat, varies for oil, water, paraffin and sand,” Schwach said. “When we started training models on a tank wall with a thermal camera 50 feet away, we could detect these differences.”

By 2018, they were ready to test their product in the field. A pilot test with BP marked the company’s official entry into the energy market. The results were so impressive that BP immediately ordered 250 more cameras, followed by another 300 cameras before the second run had even finished.

As Andium continued to develop its technology, the company integrated more sensors into the system for more scale. Its solution not only saved operators time and money by reducing field visits, but it also helped mitigate methane emissions by ensuring flare pilots remained lit.

Andium used the AI processor found in self-driving cars to manage oil tank levels and monitor flaring. Communications technology also became cheaper, allowing Andium to move away from long-range radio and use cellular networks with multi-carrier support for more reliable communication.

Schwach said Tesla CEO Elon Musk indirectly helped Andium make a key breakthrough. When Musk decided not to use Lidar technology in his vehicles, chip companies had to come up with new answers.

Andium’s new approach led to a more efficient and sensitive system. The new sensors allowed for better heat detection and integrated AI directly with the sensor package, providing raw visual and heat data in real time. Now Andium could tell methane apart from other substances like CO2, allowing operators to track leaks accurately.

While the company has experienced rapid growth, Schwach notes that the biggest challenges have been managing infrastructure and continuously updating AI models. These challenges, however, have been instrumental in developing a robust, scalable ecosystem.

“The benefit of that is that any problem that comes up in networking is one that you can solve, since you have access to everything,” he said. “But the downside is that every problem is your problem. If the network goes out because the cellular network actually goes out, that is your problem. So one of the challenges is in building the businesses and you have to gain your trust by solving these problems.”

Andium’s technology now offers operators a customized dashboard with live-streaming capabilities and integration with SCADA systems. One of the most exciting upcoming features, said Schwach, is the ability to rewind and review data, not just for individual units but for an entire area, creating a composite view of an incident.

“It used to be that you monitored images … now we monitor video, and allowing us to monitor video allows us to track things,” Schwach said. “We’re very close to being able to accurately quantify methane, and the reason we can quantify methane is that we can track it.”

Schwach sees Andium’s technology expanding further into oil and gas operations.

“Over the next 12 months, we’ll see four times the efficiency of the AI that we do today, which could mean seeing smaller leaks,” he said. “The next challenge is monitoring wellheads, where methane emissions are a significant concern.

“It’s not just about cameras anymore; we need new sensors to address these emerging problems. You think it’s a camera and it’s not, it’s really like the ability to continuously evolve all of the different things you’re doing.”

Recommended Reading

Will TG Natural Resources Be the Next Haynesville M&A Buyer?

2025-03-23 - TG Natural Resources, majority owned by Tokyo Gas, is looking to add Haynesville locations as inventory grows scarce, CEO Craig Jarchow said.

Voyager Midstream Closes on Panola Pipeline Interest Deal

2025-03-19 - Pearl Energy Investments portfolio company Voyager Midstream Holdings has closed on its deal with Phillips 66 for its non-op interest in the Panola Pipeline.

Sources: Citadel Buys Haynesville E&P Paloma Natural Gas for $1.2B

2025-03-13 - Hedge fund giant Citadel’s acquisition includes approximately 60 undeveloped Haynesville locations, sources told Hart Energy.

Japan’s Mitsui Testing Western Haynesville Alongside Comstock, Aethon

2025-03-26 - Japanese firm Mitsui has plans to drill a horizontal well in the emerging western Haynesville play as renewed foreign investment in U.S. shale continues to pick up steam.

NOG Spends $67MM on Midland Bolt-On, Ground Game M&A

2025-02-13 - Non-operated specialist Northern Oil & Gas (NOG) is growing in the Midland Basin with a $40 million bolt-on acquisition.

Comments

Add new comment

This conversation is moderated according to Hart Energy community rules. Please read the rules before joining the discussion. If you’re experiencing any technical problems, please contact our customer care team.