To lessen the “pain of intervention” during artificial lift, Baker Hughes’ Primera and InjectRT services take an innovative approach to address industry challenges. (Source: Shutterstock.com)

Artificial lift is a common practice to extract as much hydrocarbon out of the ground as possible, but even with the best tools available, meeting that goal isn’t always easy.

Tried and true methods of artificial lift, such as electrical submersible pumps (ESPs), allow producers to extract as much hydrocarbon out of the ground as possible.

ESPs are centrifugal pumps made up of multiple stages connected to a submersible electric motor, powered by heavy duty cables connected to surface controls. As the shaft of the pump rotates, spinning impellers draw in fluid through the pump intake, pressurize it and lift it to the surface.

But the complicated technology isn’t foolproof.

Using ESPs as an artificial lift method can mean high costs, electrical failure, waxing and corrosion, to name a few.

Baker Hughes has two services meant to mitigate such problems in risky, high-intervention cost applications and offshore subsea: the Primera premium artificial lift service and InjectRT intelligent chemical treatment optimization service, Tyler Shirk, Primera business leader for Baker Hughes told Hart Energy.

Used in the Gulf of Mexico, Brazil, the North Sea and other deepwater offshore areas, Primera was formed to relieve the “pain of intervention,” said Shirk.

“Intervention costs, especially if unplanned, are extremely painful and extremely difficult for the customers… they demand something much better, and that’s where the Primera service comes in,” he said.

Primera has been in operation for 15 years with proven results, said Shirk. In Brazil, a client has been using the Primera service model for the past 10 years. One of the pumps used at that field has been in use for nine years— more than twice the typical duration of four years, he said. This has led to more barrel uplift, less non-productive time and less intervention costs.

Baker Hughes is also able to apply learning from different fields in Brazil to other countries, due to the level of standardization that Primera affords operators.

“There’s a lot of differences in the completion designs, the subsea infrastructure designs, the sizes, the flow rates,” he said.

But Baker Hughes employs the same systems engineering team and project management team for projects around the world to employ what they’ve learned to improve technology, metallurgy, polymers and equipment and application design.

Because of this, Baker Hughes was able to solve similar challenges in Brazil that they first encountered in Europe, Shirk said.

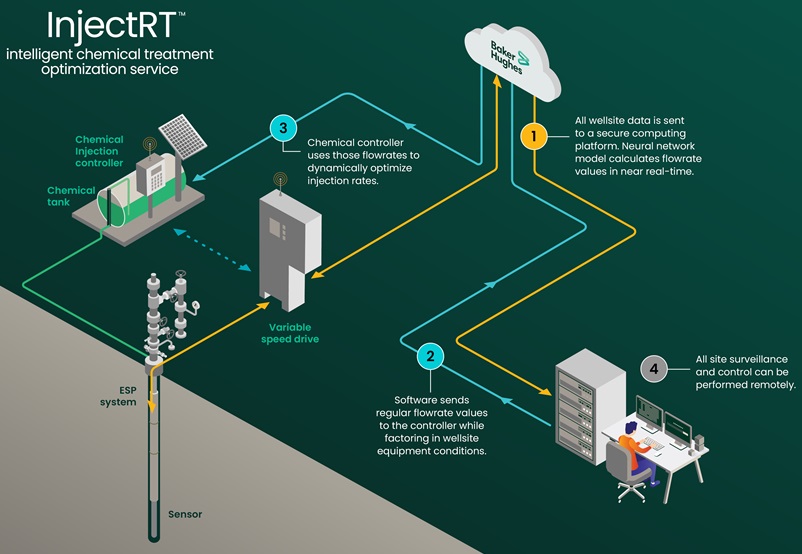

Another service in Baker Hughes’ ESP solution suite is its InjectRT service, which addresses challenges with chemical injections within the well.

“People are always looking for ways they can avoid ESP early failures,” Nick Styles, Baker Hughes’ product manager for edge computing, told Hart Energy. “One of the big things is the chemistry—and we see more and more that if you don’t get that application right then it’ll damage your assets.”

The company’s InjectRT tool ensures the proper amount of chemical dosing for your well based upon intelligent, real-time insights garnered from your ESP.

“We’re combining our ESP knowledge, our expertise and all of our tools in terms of digital twins and digital software and techniques that we can use to analyze ESPs and apply them in real time. We use that data from that digital analysis to provide a high accuracy, high precision injection and autonomous workflow,” Styles said.

The core of InjectRT is the digital model of the ESP, Styles said. Using its AutographPC software to size the pump, Baker Hughes collects the base data needed to model the pump and then feeds it with real-time information. This allows them to adapt and configure solutions to the best fit of the well.

“We find that most of the other solutions out there try to look at the real-time adjustments of the injection based on the flow rate from the well, they tend to use traditional flow meters and the way they measure actually not very accurate,” he said.

But Baker Hughes’ solution is more accurate than traditional systems using traditional meters, he said.

Permian Basin applications

While the Primera service is still looking to grow onshore, the InjectRT service has made waves in the Permian with operators facing issues with over and under chemicals within their wells. InjectRT was able to use its automation capabilities to precisely adjust and operate the chemical being injected in the well, removing the need for manual intervention.

“We were able to avoid three field trips per month, which was a big deal for the customer as they were conscious that they were doing too many trips to the well site to look at upticks on tanks and other things that really weren’t efficient,” Styles said.

As both platforms continue to advance, Baker Hughes looks to incorporate its Leucipa automated field production solution into each, said Shirk. A joint collaboration with Amazon Web Services, Leucipa uses AI and machine learning to tell operators exactly what their well needs to optimize its production.

“The Leucipa platform is about allowing our customers to do more with less,” he said. “It’s not taking the experience and the human being out the equation, it’s just giving you tools that will amp up your productivity level.”

As Baker Hughes continues to innovate with its Primera and InjectRT services, the company aims to reduce operational challenges and enhance efficiency for offshore and onshore operators alike. By leveraging advanced technology and real-time data, Baker Hughes intends to meet the evolving demands of the energy sector while driving down costs and increasing production reliability.

Recommended Reading

Aethon Dishes on Western Haynesville Costs as Gas Output Roars On

2025-01-22 - Aethon Energy’s western Haynesville gas wells produced nearly 34 Bcf in the first 11 months of 2024, according to the latest Texas Railroad Commission data.

Matador Touts Cotton Valley ‘Gas Bank’ Reserves as Prices Increase

2025-02-21 - Matador Resources focuses most of its efforts on the Permian’s Delaware Basin today. But the company still has vast untapped natural gas resources in Louisiana’s prolific Cotton Valley play, where it could look to drill as commodity prices increase.

Antero Stock Up 90% YoY as NatGas, NGL Markets Improve

2025-02-14 - As the outlook for U.S. natural gas improves, investors are hot on gas-weighted stocks—in particular, Appalachia’s Antero Resources.

BP’s Eagle Ford Refracs Delivering EUR Uplift, ‘Triple-Digit’ Returns

2025-02-14 - BP’s shale segment, BPX Energy, is seeing EUR uplifts from Eagle Ford refracs “we didn’t really predict in shale,” CEO Murray Auchincloss told investors in fourth-quarter earnings.

Back to the Future: US Shale is Growing Up

2025-01-07 - The Patch’s maturity will be tested in 2025 amid ongoing consolidation and geopolitical dissonance.

Comments

Add new comment

This conversation is moderated according to Hart Energy community rules. Please read the rules before joining the discussion. If you’re experiencing any technical problems, please contact our customer care team.