E&P Magazine - February 2018

Digital

This month E&P takes a step back to the basics with a look at how operators are identifying the best locations to place subsea equipment during the field development phase. Other stories include a dive into the considerations made during the design and selection process of subsea production systems. Also covered is a new digital platform that integrates robotics, artificial intelligence and original predictive analytics to advance subsea inspection services. The section wraps up with up with an overview of how operators are bringing together current infrastructure with future subsea projects.

As I See It

Facing A Changed Future

A slimmer and trimmer offshore segment emerges in 2018.

Cover Story

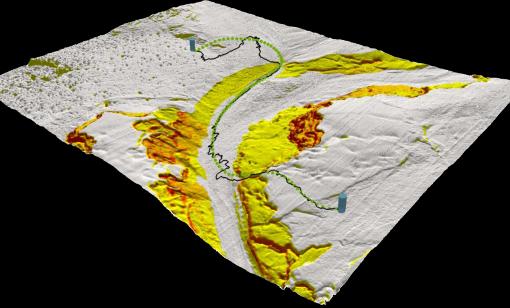

Back To Basics On Seabed Surveys

Before deploying subsea development strategies, operators need to know where their equipment is going.

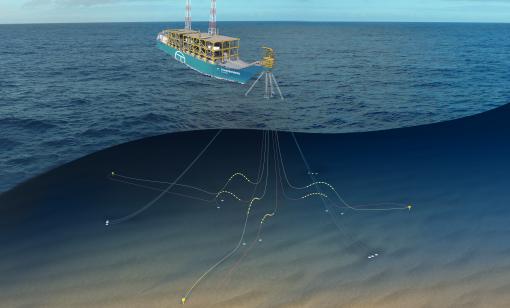

Bright Future: New Projects Keep Subsea Flowing

This month E&P takes a step back to the basics with a look at how operators are identifying the best locations to place subsea equipment during the field development phase.

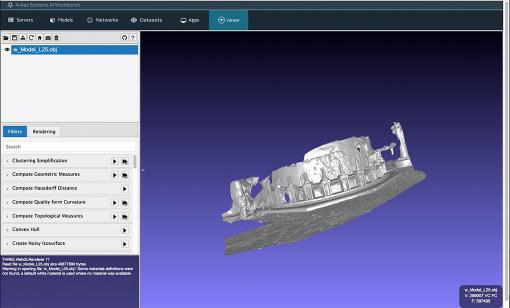

Digitally Transforming Inspection Services

A platform integrates robotics, AI and original predictive analytics to advance the inspection services industry.

Making The Most Of Offshore Infrastructure

Operators find subsea success by using existing infrastructure off the Norwegian coast.

Optimizing System Design And Field Architecture

An integrated SPS/SURF and alliance approach delivers sustainable improvement in field development value.

Industry Pulse

The Vibration Threat

Web tools enable effective piping vibration management.

Market Intelligence

A Sandstorm Is Coming

The move to massive proppant loading involving finer mesh sands will boost 2018 demand even in a flat rig count environment.

Exploration Technologies

Innovation In A Downturn

Maintaining discipline and patience can pay dividends in an R&D program.

Drilling Technologies

NDT Shaves Days Off BOP Inspection Time

Digital solution reduces downtime and cost while improving productivity for offshore drilling operations.

Completions and Production

Extend Production By Maintaining Oilfield Equipment

Maintenance programs can help save costs and enhance long-term production.

Offshore Advances

OSVs Evolve To Survive

The new ‘normal’ is a catalyst for change.

Digital Solutions

Solving Upstream’s Data Trust Gap

A robust technology system delivers directly measured multiphase metering data for improved operations.

Shale Solutions

Managing Well Development With A Manufacturing Mindset

The upstream oil and gas industry has managed its operations the same way for decades because ‘We’ve always done it that way.’

Offshore Solutions

Unlocking The World’s Smaller Offshore Gas Assets

A concept using small FLNG vessels for stranded fields will save the industry billions of dollars.

Operator Solutions

Accurately Representing Fracture Flow In Reservoir Simulation

Intuitive analysis helps prevent slow or inaccurate predictions.

Harnessing The True Potential Of IoT

Predicting equipment downtime through IoT solutions can save operators time and money.

Features

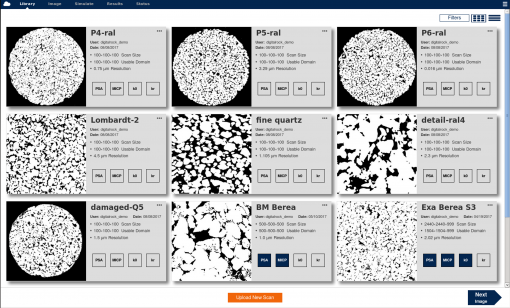

A Critical Element For Understanding The Subsurface

An understanding of rock physics is crucial for reservoir characterization.

Answering Borehole Stability Challenges In Difficult Shale

Formate fluids help slow pressure transmission in the wellbore.

Facies-based Inversion Through The Asset Life Cycle

A research study indicated that a facies-based seismic and CSEM inversion provides useful information.

Flat Rheological Fluid System Safely Achieves Drilling Objectives

A drilling fluid system combines chemistry, software and logistics to deliver solutions for challenging deepwater wells.

Flow Assurance Evolves

Improved products and expanded services deliver gains for subsea production.

Getting A Handle On Sand Production

Sand-handling technologies protect equipment and reduce costs.

Improving Safety Through Advanced Composite Technology

Novel approach saves time and reduces risk for offshore casing installations.

Improving Well Economics With Advanced Proppants

Altering the surface chemistry of resin-coated proppant delivers improved oil flow rates in the Eagle Ford Shale.

Managing Sand Production During A Downturn

As usage grows, technologies emerge to face new completion production challenges.

Simulating Relative Permeability

A new software program helps operators model multiphase flow.

Unconventional Report

Haynesville Shale Play Continues Its Climb

This region’s gas production equals predownturn levels.

Tech Watch

A Highlight In Carbon Reduction

A new photocatalytical process promises to reduce greenhouse gases.

Tech Trends

Tech Trends

Check out the latest technology product releases.

Activity Highlights

International Highlights

Check out the latest activity highlights from around the world.

On The Move

On the Move

Check out the latest new hires, promotions and appointments.

Last Word

AI Shaping The Future Of Oil And Gas

Four critical automation areas are paving the road for longer-term AI.