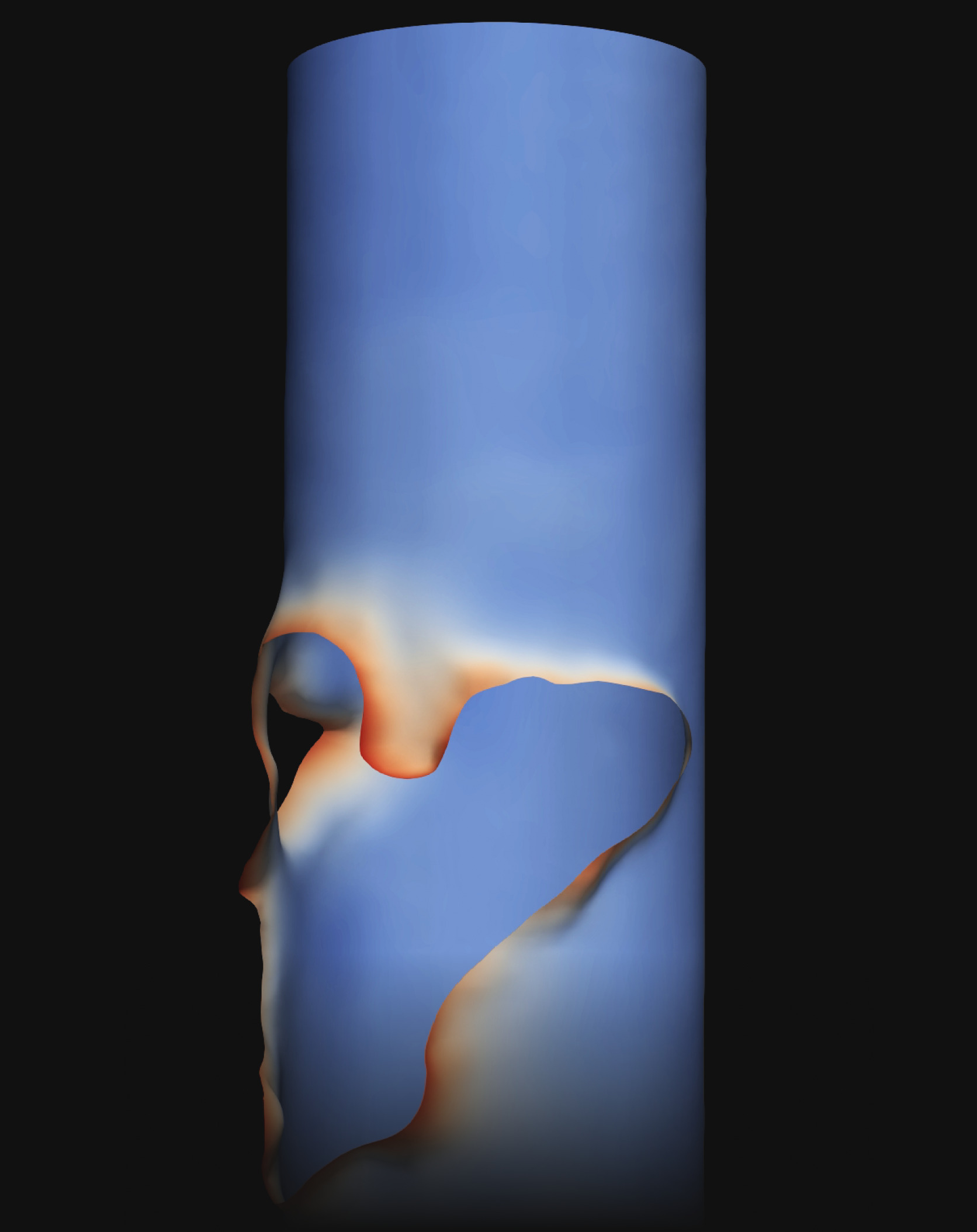

DarkVision’s HADES platform provides unprecedented clarity downhole, delivering remarkable detail to wellbore inspection, the company says. (Source: Shutterstock)

DarkVision’s HADES downhole technology may evoke the nefarious god of the underworld, but the imaging tool is decidedly more geek than Greek.

The company’s High-Resolution Acoustic Downhole Evaluation System—branded as HADES—offers a “super high resolution, acoustic-based imaging technology,” according to DarkVision CEO Stephen Robinson.

The company pitches the tech as a “step change” advancement for illuminating the inspection of downhole assets, DarkVision vice president of sales Chris McCann told Hart Energy.

The imaging quality, he said, elicits astonishment from grizzled drilling veterans—and it's kid friendly, too.

“It makes downhole issues and visualization of downhole components very easy. We put everything into three dimensions and it’s ultra-high resolution, so it gives you a way to look at things in the downhole space in a way that no other tool or combination of tools on the planet can,” he said.

HADES’ core functionality provides ultra-high-resolution, 3D imaging of downhole spaces. Most imaging tools struggle to visualize components such as sliding sleeves or damaged casing. Canada-based DarkVision’s technology fills in those gaps. With resolutions of 100th of an inch —and the capacity to scan multiple casing sizes in a single run—the HADES platform ups productivity and coverage, McCann said.

“It’s very high resolution, but it’s also very efficient,” he said. “The scanning speed is the same, but you get super high resolution coverage of the entire well bore in the same amount of time.”

HADES enables operators to detect minute details, such as pitting, as well as granular detail: numbers stamped on pipes are readable.

A key challenge faced by DarkVision was processing the massive datasets generated by the high-resolution imaging.

“One of the ramifications of collecting really high resolution and high-quality data is that you end up with these enormous datasets,” Robinson said. “The act of storing them, compressing them, rendering them and turning them into a 3D model for customers was a huge endeavor. So as a result of that, we have a big mechanical engineering team, a huge electrical and electronics engineering team and an even bigger software engineering team,” Robinson said.

Once data is collected, HADES processes it into smaller and more discrete, actionable versions that are deliverable to customers.

Critical scenarios

The HADES platform comprises several product lines, each designed for specific inspection needs.

The HADES-R and HADES-T perform radial inspections that provide a continuous 360-degree scan of the wellbore. The HADES-T specializes in imaging casing thickness, offering a super high-resolution view to assess wall loss.

HADES-F introduces a robotic head component that allows for direct downhole imaging— particularly useful for identifying obstructions or inaccessible areas within the wellbore.

The significance of the advancement is underscored by its application in critical scenarios, Robinson said.

“You often have a collapsed casing, some kind of obstruction or something you can’t get past. [HADES-F] is built on a robotic head that allows it to be parked at the stuck object. And then the tool itself physically moves around and does an imaging scan using a robotic head,” Robinson said. “It’s kind of the same technology built on a movable robotic head that allows it to do a really high resolution scan, but only of a particular area.”

The platform has been instrumental in inspecting damaged casing, verifying the status of sliding sleeves and evaluating perforations. Those functions have saved operators time and costs while ensuring operational integrity. In addition to Shell and BP, which Robinson says are “the two main clients that [DarkVision has served]…in the Gulf of Mexico.”

DarkVision has also provided imaging to E&Ps including ConocoPhillips, Arc Energy, Devon, SM Energy and Chevron.

“In deepwater, things are much more complicated, they’re much more high value, there’s much more risk and dollar risk with these types of operations. Things like sliding sleeves and damage at connections are really hard for current technologies to visualize and inspect those types of components,” McCann said. “DarkVision and the HADES tool are very good at inspecting those types of components.”

Despite the complexity of the technology underlying the HADES Platform, DarkVision prioritizes simplicity and actionable insights.

“The technology is very complicated, but we work really hard to make sure that the outputs are simple and easy for people to understand—to the point where if I’m showing it to my kids, they’ll understand it,” said McCann. “I can tell you from experience that when I put these models and these images up for hardened field superintendents in a presentation, the first time they’ve [seen] it, you literally heard gasps from the back of the room. There was genuine disbelief.”

DarkVision is also looking to expand its services internationally, opening offices in Saudi Arabia and Norway while also expanding uses for the HADES platform.

McCann said the technology can lend itself to a variety of applications, from “slotted liner, screen completions or use in things like cavern storage or carbon sequestration.”

“The technology is so different that, as we use it more, we keep finding new and interesting use cases,” he said.

Recommended Reading

Velocity Management Invests in Pipeline Builder M Wright Services

2025-01-16 - Velocity Management Advisors has made a minority investment in M Wright Services and three of Velocity’s partners will join the construction firm’s board.

New Fortress Makes Headway on $2.7B Debt Refinancing

2024-11-26 - New Fortress Energy Inc. anticipates raising approximately $325 million in gross proceeds through the refinancing.

TC Energy Appoints Two Independent Directors to Board

2024-11-07 - TC Energy Corp. appointed Independent Directors Scott Bonham and Dawn Madahbee Leach to its board, the company announced Nov. 7 in a press release.

Record NGL Volumes Earn Targa $1.07B in Profits in 3Q

2024-11-06 - Targa Resources reported record NGL transportation and fractionation volumes in the Permian Basin, where associated natural gas production continues to rise.

Venture Global LNG Pares IPO Hopes by 15% to $2.2B

2025-01-22 - LNG exporter Venture Global nearly halved the price per share, while increasing the number of shares it expects to offer.

Comments

Add new comment

This conversation is moderated according to Hart Energy community rules. Please read the rules before joining the discussion. If you’re experiencing any technical problems, please contact our customer care team.